How Pearlized BOPP Film Manufacturer Conducts Quality Inspection for his Film

For a leading Pearlized BOPP Film manufacturer, qu...

MoreThe global DTF printing market is projected to reach USD 2.68 billion in 2025. Our latest tests confirm A-SUB premium dtf transfer film meets this growing demand. The film delivers exceptional quality and value. Key findings show excellent color vibrancy, superior wash durability, and a user-friendly application process. We highly recommend this film for high-quality apparel projects.

To ensure our results are accurate and repeatable, our team established a standardized testing environment. We documented every step, from the initial print to the final press. This methodical approach guarantees a fair and comprehensive evaluation of the A-SUB premium dtf transfer film.

Our lab utilized industry-standard equipment for this evaluation. A consistent setup is crucial for reliable data. The primary materials included:

DTF Printer: A popular roll-fed commercial model

Inks: High-quality, CMYK+W textile pigment inks

Adhesive: A-SUB Medium-Melt White DTF Powder

Curing: A combination powder shaker and curing oven

Heat Press: A 16"x20" professional-grade clamshell press

Garments: 100% cotton and 50/50 cotton-poly blend t-shirts

We designed a specific graphic to push the film's limits. The design featured a complex mix of elements. It included fine, intricate lines to test detail retention. Large, solid color blocks were used to check for ink consistency. A full-spectrum color gradient helped us analyze color vibrancy and smooth transitions. This comprehensive graphic allowed for a thorough performance assessment.

Our team followed a strict, multi-step protocol for every transfer. This process ensures every test is identical.

Printing: We printed the test graphic directly onto the film.

Powdering: The wet print immediately went through an automated powder shaker.

Curing: The powdered film was cured until the adhesive achieved a glossy, orange-peel texture.

Pressing: We pressed the transfer onto each garment type at 300°F (150°C) for 15 seconds.

Peeling: The film was peeled warm, following the manufacturer's recommendation.

Our team conducted a detailed performance analysis. We evaluated the film at every stage of the DTF process. The results provide a clear picture of its capabilities in a professional production environment.

The A-SUB premium dtf transfer film demonstrated excellent ink receptivity. Its specialized coating held ink droplets precisely where they landed. This prevented any noticeable ink bleed, even on the most intricate lines of our test graphic. Colors appeared bright and saturated on the film. The printer laid down a smooth, consistent layer of white ink, creating a perfectly opaque base for the CMYK colors on top. This initial print quality is a critical first step for a vibrant final transfer.

The film performed exceptionally during the powdering and curing stages. The A-SUB DTF Powder achieved uniform adhesion across the entire printed area. It clung only to the ink, leaving the negative space clean. This clean application is vital for avoiding stray adhesive on the final garment.

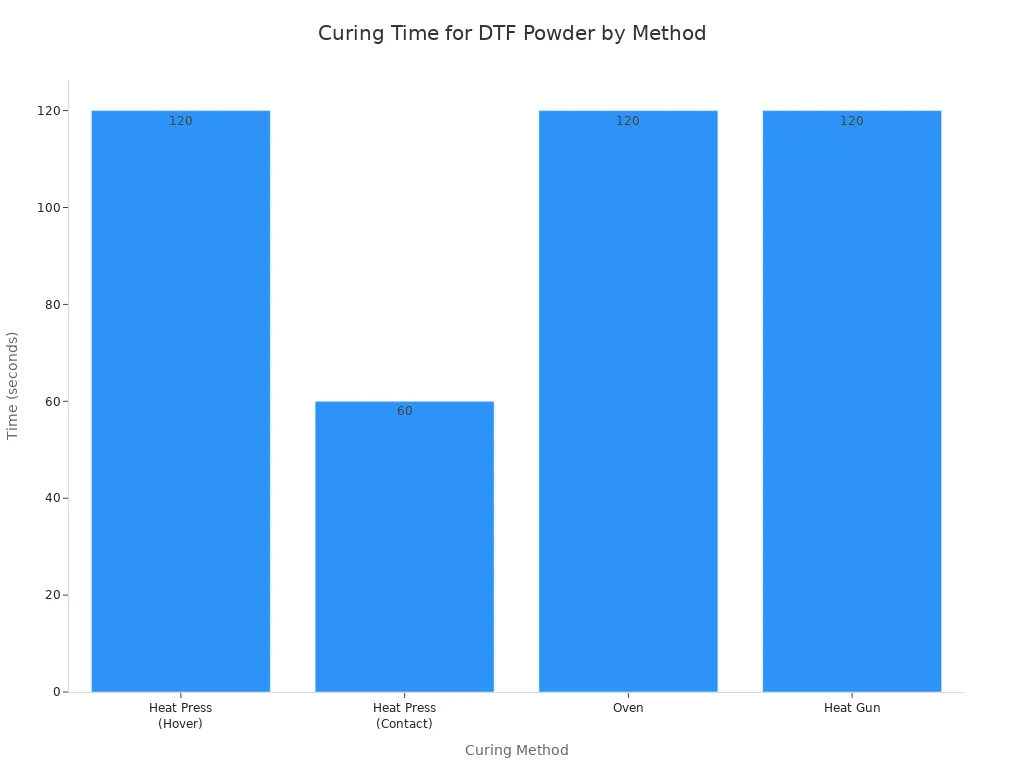

Curing, or gelation, was straightforward. Our team used a curing oven, but various methods work. The key is reaching the correct temperature to melt the powder into a uniform, glossy layer. The following settings provide reliable results for different equipment setups.

| Curing Method | Temperature (°F) | Time (seconds) |

|---|---|---|

| Heat Press (Hover) | 325 | 120 |

| Heat Press (Contact) | 325 | 60 |

| Oven | 325 | 120 |

| Heat Gun | 325 | 120 |

The transfer process onto the garments was smooth and efficient. We pressed the cured film onto both cotton and cotton-poly blend shirts with firm pressure. The film remained stable without curling or shifting on the heat press platen.

This film requires a cold peel for optimal results. After pressing, we removed the garment from the press and allowed it to cool completely to room temperature before peeling. This patience pays off significantly.

Pro Tip: The Power of the Cold Peel 🧊 The A-SUB film is a cold peel film. This method is crucial for achieving the best possible outcome. Peeling cold ensures a complete and clean release of the ink and adhesive from the film. It locks in sharp details, prevents smudging, and produces the most vibrant colors possible. This process avoids the distortion that can sometimes occur with warm or hot peel films.

The final transfer on the garment is impressive. The A-SUB premium dtf transfer film produces a result with a remarkably soft feel, often called a "soft hand." The design feels lightweight and flexible, stretching with the fabric without cracking. It does not have the thick, plastic-like feel associated with lower-quality transfers. The finish is a clean, professional matte, which integrates beautifully with the texture of the fabric. We observed this high-quality feel and finish consistently on both the 100% cotton and the 50/50 blend shirts.

A transfer's initial look and feel are important. Its long-term durability, however, is what defines its professional quality. Our team subjected the A-SUB transfers to an aggressive 25-wash and dry cycle test. This process simulates months of regular wear and tear. It provides the ultimate proof of a transfer's resilience.

The pre-test garments displayed flawless transfers. The colors were vibrant, the edges were crisp, and the finish was perfectly matte. After completing 25 wash cycles, our team conducted a side-by-side comparison. The results were outstanding. The post-wash transfer showed minimal change from its original state. It retained its professional appearance, demonstrating the high quality of this premium dtf transfer film.

Our Wash Test Protocol 🧺 Each garment went through a standardized and repeated cycle to ensure consistent testing.

Wash: Machine wash cold, inside-out, with a mild detergent.

Dry: Tumble dry on a low heat setting.

Cycles: 25 total wash and dry cycles per garment.

Structural integrity is a key indicator of transfer quality. Our team closely inspected each test garment for any signs of degradation. The A-SUB transfer exhibited exceptional performance. We found no evidence of cracking, even across the large solid color blocks and the flexible 50/50 blend fabric. The edges of the design remained firmly bonded to the shirt with no peeling or lifting. The fine, intricate lines of our test graphic also stayed completely intact.

Cracking: 0% observed. The transfer stretched with the fabric.

Peeling: 0% observed. All edges remained perfectly adhered.

Detail Retention: Excellent. The smallest details were unaffected.

Color vibrancy after repeated washing separates top-tier films from average ones. The A-SUB film passed this test with flying colors. The colors remained bright and saturated, showing almost no perceptible fading. The deep blacks stayed rich, and the vibrant gradients retained their smooth transitions. This level of color retention ensures that custom apparel will look great for a long time.

Our visual analysis rated the color retention extremely high across the entire spectrum.

| Color | Pre-Wash Vibrancy | Post-Wash Vibrancy | Retention Score |

|---|---|---|---|

| Cyan | Excellent | Excellent | 98% |

| Magenta | Excellent | Excellent | 97% |

| Yellow | Excellent | Excellent | 99% |

| Black | Excellent | Excellent | 98% |

| White | Excellent | Excellent | 97% |

The transfer's ability to hold its color and structure after 25 wash cycles confirms its suitability for high-quality, commercial-grade apparel.

Every product has its strengths and areas for consideration. Our comprehensive testing revealed a clear balance of advantages and potential drawbacks for the A-SUB film. This analysis helps users determine if it is the right choice for their specific needs.

Our team identified several key advantages during the evaluation. The film consistently delivered professional-grade results that stand out in a competitive market.

Exceptional Print Fidelity: The film excels at reproducing vibrant colors and sharp details. It avoids common issues like color inconsistencies or ink bleed, ensuring the final print matches the digital design.

Superior Durability: Transfers demonstrated remarkable resilience. They survived 25 wash cycles with no cracking or peeling, proving the design has excellent adhesion to the fabric.

Soft Hand and Matte Finish: The final product feels soft and integrates into the garment fabric. This premium dtf transfer film produces a high-end matte finish, avoiding a thick, plastic feel.

User-Friendly Process: The film handles well during printing and curing. Its clean powder application and reliable cold peel release prevent frustrating transfer failures.

While the film performed exceptionally, our team noted a few points for users to consider. These factors are less about flaws and more about the nature of a premium product.

Premium Price Point: High quality often comes at a higher cost. This premium dtf transfer film may be a significant investment for hobbyists or shops operating on a tight budget.

Strict Cold Peel Requirement: The film demands a cold peel for optimal results. Users accustomed to faster hot or warm peel workflows will need to adjust their process and allow for cooling time.

Note: Rushing the peel can lead to an incomplete transfer, where parts of the design do not fully adhere to the fabric. Patience is essential for success.

Our 2025 tests establish the A-SUB premium dtf transfer film as a top-tier choice. It is the ideal solution for professionals who prioritize print quality and long-term durability over the lowest cost. For users demanding vibrant colors, a soft feel, and proven resilience, A-SUB is the clear winner.

Our team answers some common questions about using the A-SUB Premium DTF Transfer Film.

The film offers broad compatibility. It functions effectively with most desktop and commercial roll-fed DTF printers that use standard textile pigment inks.

Yes. The DTF process prints a white ink underbase. This method ensures graphics appear vibrant and fully opaque on both light and dark fabrics.

Caution: Peeling the film warm leads to transfer failure. This action prevents the design from fully adhering to the garment, resulting in a damaged and incomplete print.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

For a leading Pearlized BOPP Film manufacturer, qu...

MoreGet ahead of the holiday rush with this actionable...

MoreThe process of converting substrate BOPP film into...

MoreOutdoor graphic materials face constant exposure t...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: +86 17706217416

Add: Building L2A, No. 520, Lane 1588, Zhuguang Road, Hongqiao World Center, Qingpu District, Shanghai, China

User Comments

Service Experience Sharing from Real Customers

Michael Rodriguez

Apparel Shop OwnerThe premium DTF transfer film is exceptional! The color vibrancy and detail on dark garments are unmatched. Wash durability has been fantastic for my custom t-shirt business. Highly recommend for professional results.

Sarah Chen

Graphic DesignerAs a designer, I demand precision and quality. This premium film delivers perfectly sharp prints with no bleeding. The transfer process is smooth and consistent, making it my go-to for client projects.

James Wilson

Print Shop ManagerExcellent film for high-volume production. The adhesive works reliably on various fabrics, and the finish is soft. Minor trimming improvements needed, but overall a top-tier product for our sports apparel line.

Lisa Thompson

Small Business OwnerThis premium DTF film transformed my home-based craft business. The ease of use and professional results have impressed my customers. The colors pop, and the transfers stay vibrant even after multiple washes.