The Pros and Cons of DTF film printing: A Comprehensive Guide

In the dynamic world of custom apparel printing, b...

More

DTF direct to film printing is a revolutionary apparel customization technique. The process prints a design onto a specialized film. An adhesive powder and heat then transfer the design directly onto a garment.

Note: Its primary advantage is fabric versatility. This method works exceptionally well on cotton, polyester, blends, and even leather, all without requiring any pre-treatment.

DTF printing puts designs on many types of fabric. It works on cotton, polyester, and even leather.

The DTF process uses special ink and powder. This makes prints bright, strong, and long-lasting.

DTF printing is good for small orders. It costs less to start than other printing methods.

The dtf direct to film printing process transforms a digital design into a wearable, durable graphic through a systematic, multi-step method. Each stage plays a critical role in achieving a high-quality final product. The process is precise, combining specialized inks, adhesives, and heat to create stunning custom apparel.

The journey begins with a specialized DTF printer. This printer does not print directly on the garment. Instead, it prints the design onto a sheet of specialized PET (polyethylene terephthalate) film. The printer first lays down the CMYK color layer. Afterward, it prints a crucial white ink layer on top. This white layer acts as the base of the design, ensuring colors appear vibrant and opaque, especially on dark-colored fabrics.

Pro Tip: Achieving optimal color vibrancy requires careful file preparation and printer settings. Professionals often follow specific guidelines to maximize print quality.

They convert RGB image files to a CMYK color profile for better print accuracy.

They create a dedicated white ink layer to serve as an opaque underbase.

A slight "choke" of 0.1-0.3mm is added to the white underbase. This technique prevents any white ink from peeking out around the edges of the final design.

Printers may use 'double white' settings for maximum opacity on black or dark garments.

While the ink on the PET film is still wet, the operator applies a special adhesive powder. This fine, granular powder sticks only to the printed ink, not the blank areas of the film. For consistent results, using a DTF powder shaker or an automated powder application machine is a best practice. These machines ensure an even coating across the entire design, which helps prevent defects in the final print.

The adhesive powders themselves are advanced polymers. Most are based on thermoplastic polyurethane (TPU), co-polyester (CoPES), or co-polyamide (CoPA) variants. For example, some popular brands like Ecofreen use a polyurethane resin-based formula. After application, the operator shakes off any excess powder, leaving a clean, precise layer of adhesive ready for the next step.

Next, the prepared film goes through a heating process to cure the transfer. The film is placed in a curing oven or under a heat press set to hover mode, where it is heated without direct contact. This heat melts the adhesive powder. The molten powder forms a uniform, rubbery layer that bonds securely with the ink.

This chemical process transforms the separate ink and powder layers into a single, durable, and washable graphic. For advanced applications on challenging materials like spandex or leather, some professionals use a plasma treatment. This treatment increases the reactive surface groups on the powder, helping the adhesive "grab" onto the fabric for an even stronger bond.

The final step is transferring the design from the film to the fabric. The operator places the cured film onto the garment in the desired position. A commercial heat press then applies controlled heat and pressure to the film. This heat reactivates the adhesive layer, bonding the ink permanently to the fibers of the fabric.

After pressing for the specified time (typically 15-20 seconds), the operator opens the press. The film is then peeled away, leaving only the vibrant, smooth design on the garment. The result is a high-quality, full-color print that is flexible, durable, and feels great to the touch.

Deciding on the right apparel printing method depends on project goals, budget, and desired outcomes. DTF printing offers a compelling set of advantages that make it a leading contender for many creators and businesses. Its unique process provides a balance of quality, versatility, and efficiency that other methods struggle to match.

A primary benefit of DTF is its ability to work with an extensive range of materials. Unlike methods limited to specific fiber types, DTF transfers adhere beautifully to cotton, polyester, and cotton/poly blends. The technology also excels on materials that are traditionally difficult to print on, such as leather, denim, and canvas. This opens up a world of creative possibilities beyond just t-shirts.

Note: DTF even works on challenging synthetic fabrics, though operators must adjust their process for the best results.

Nylon is suitable for DTF transfers. It requires careful heat management because it can melt under high temperatures.

Spandex fabrics also accept DTF transfers. Printers need to pay close attention to printing parameters to prevent stretching or distorting the design.

DTF prints are known for their striking visual quality and durability. The process uses a white ink underbase, which ensures that colors appear bright and opaque, even on the darkest garments. The melted adhesive powder creates a strong bond with the fabric fibers, resulting in a print that resists cracking, peeling, and fading. These prints are flexible and can withstand numerous wash cycles while maintaining their original vibrancy. The final graphic feels smooth and integrated into the garment.

DTF printing is an exceptionally economical choice for small to medium-sized orders. The process avoids the extensive setup required for methods like screen printing. There are no screens to create or complex color separations to manage. An operator can print a single, full-color design or ten different designs with minimal initial effort. This efficiency makes DTF ideal for custom one-offs, sample runs, and limited-edition product drops, allowing businesses to offer personalization without requiring large minimum orders.

Direct to Garment (DTG) printing applies ink directly into the fabric's fibers, while dtf direct to film printing transfers a completed design from a film onto the fabric. This core difference leads to distinct outcomes in feel, cost, and material compatibility. DTG is largely restricted to cotton or high-cotton blend garments and requires a pre-treatment liquid. DTF, however, bypasses these limitations.

DTF prints often have a slightly thicker, more plastic-like feel. This is due to the adhesive layer and film transfer process.

DTG prints, in contrast, tend to have a softer, more integrated feel because the ink absorbs directly into the fabric fibers.

The initial investment also differs significantly. A starter DTF setup is far more accessible for new businesses.

| System Type | Initial Equipment Cost Range |

|---|---|

| DTF Printing | $2,000 to $5,000 |

| DTG Printing | $10,000 to $30,000 or more |

Screen printing is a traditional powerhouse for high-volume apparel production. It involves pushing ink through a mesh screen onto fabric, with a separate screen required for each color in a design. While highly efficient for large orders, its setup is time-consuming and costly for small jobs.

DTF shines where screen printing is impractical. It handles intricate, multi-color designs without any additional setup per color. For small orders, DTF is much faster from start to finish. However, for large-scale production, screen printing's speed is unmatched once the initial setup is complete.

Screen Printing: After the initial setup, automated presses can print hundreds of pieces per hour. This makes it the ideal choice for high-volume bulk orders.

DTF Printing: This method is great for producing quick single items or small batches. Its production rate is inherently slower than an industrial screen press, making it a risky choice for large deadlines, such as an order of 1,000 units.

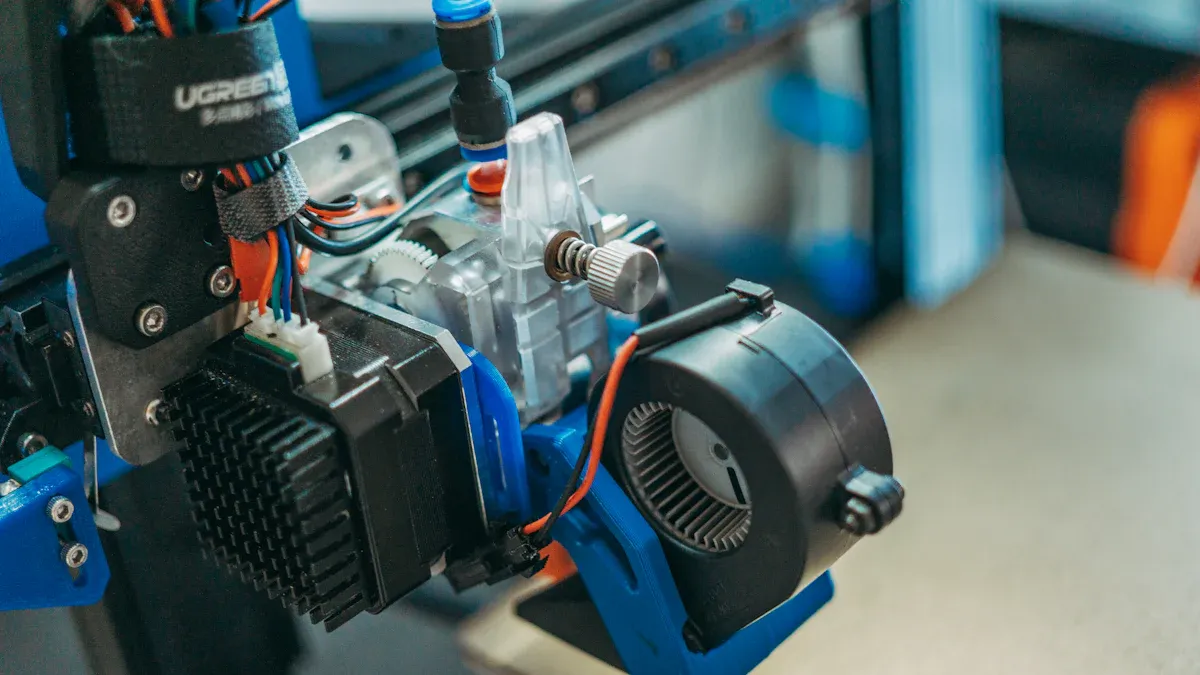

Assembling the right equipment is the first step toward mastering dtf direct to film printing. Each component plays a specific role in the production workflow, from initial design printing to the final press. Understanding these tools is essential for achieving professional-grade results.

A specialized DTF printer is the core of any setup. These machines are engineered to handle PET film and use a specific ink configuration. They print a full-color CMYK layer first, then apply a white ink overprint. This white ink is crucial for creating an opaque base that makes colors pop on any garment color.

Designs are printed onto specialized PET (polyethylene terephthalate) films, not directly onto fabric. These films are designed to accept the ink and release it cleanly during the heat press stage. Films come in different varieties, such as hot peel or cold peel, which dictates when the operator removes the film after pressing.

This fine thermoplastic powder is the "glue" that binds the print to the fabric. After printing, the operator coats the wet ink with the powder. Proper storage of this powder is critical for preventing clumps and ensuring quality.

Pro Tip: To maintain powder quality, operators should follow strict storage guidelines.

Store the powder in a cool, dry place away from sunlight.

Keep containers sealed tightly to block out moisture.

Use desiccant packets inside the container to absorb any ambient humidity.

Reseal the container immediately after each use.

A quality heat press is non-negotiable for the final transfer. It applies the precise heat and even pressure needed to bond the design permanently. Operators choose between two main types: clamshell and swing-away.

| Feature | Clamshell Heat Press | Swing-Away Heat Press |

|---|---|---|

| Design | Top platen lifts up on a hinge. | Upper platen swings away from the base. |

| Space | Compact and space-saving. | Requires more operational room. |

| Safety | Higher burn risk due to heat exposure. | Safer, as the hot platen moves away. |

| Pressure | May be uneven on thick items. | Distributes pressure more evenly. |

| Cost | Generally lower cost. | More expensive. |

Choosing the right press depends on workspace, budget, and the types of items an operator plans to produce.

The dtf direct to film printing method offers a versatile and accessible path to custom apparel. It produces durable, high-quality graphics on a wide range of materials. This makes it an excellent choice for beginners and small businesses. Creators can explore starter kits to begin their first project.

DTF prints are highly durable. They resist cracking, peeling, and fading through numerous wash cycles. The strong adhesive bond ensures the graphic remains vibrant and intact for a long time.

No, a standard inkjet printer is not suitable. 🚫 DTF requires a specialized printer engineered to handle PET film and use specific DTF inks, including the essential white ink layer.

The final print feels smooth and flexible on the garment. It has a slightly thicker texture compared to DTG prints but integrates well with the fabric without feeling overly heavy.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

In the dynamic world of custom apparel printing, b...

MoreFlexo printing uses flexible plates to create high...

MoreWhen it comes to transferring designs onto objects...

MoreWhen diving into Direct-to-Film (DTF) printing, on...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: +86 17706217416

Add: Building L2A, No. 520, Lane 1588, Zhuguang Road, Hongqiao World Center, Qingpu District, Shanghai, China

User Comments

Service Experience Sharing from Real Customers

James Wilson

Marketing DirectorThe DTF printer has revolutionized our custom apparel business. The print quality is exceptional, with vibrant colors and incredible detail on dark fabrics. It's fast, reliable, and has significantly expanded our product offerings.

Sarah Chen

Studio OwnerAs a small business owner, investing in DTF direct-to-film printing was the best decision. The setup is straightforward, and the prints are soft, durable, and perfect for our limited-run designs. Customer satisfaction has soared since we started using this technology.

Michael Rodriguez

Production ManagerOur DTF printing system has dramatically increased our production capacity and reduced waste. The color consistency and adhesion on various fabrics, including polyester blends, are outstanding. It's a game-changer for our promotional products line.

Emily Foster

Graphic DesignerThe creative possibilities with DTF printing are endless. I can now translate intricate, full-color designs onto garments with perfect clarity and a soft hand feel. It's incredibly reliable and has become an indispensable tool in our design and fulfillment workflow.