What is DTF

In the dynamic world of fabric printing, the quest...

MoreThe Direct-to-Film (DTF) printing market is expanding, driven by demand for custom apparel. Businesses entering this space face a choice between material formats. Startups often select A3 DTF PET film sheets for their low cost. In contrast, established operations choose film rolls to maximize production speed and reduce costs.

| Metric | Value |

|---|---|

| 2024 Market Size | USD 2,720.0 million |

| 2030 Projected Market Size | USD 3,920.0 million |

| CAGR (2025-2030) | 6.0% |

Businesses choose A3 DTF sheets for their accessibility and ease of use. This format is an excellent entry point for startups, small-scale operations, and companies specializing in low-volume, custom orders. The manageable size and lower upfront commitment make it a practical choice for testing the market.

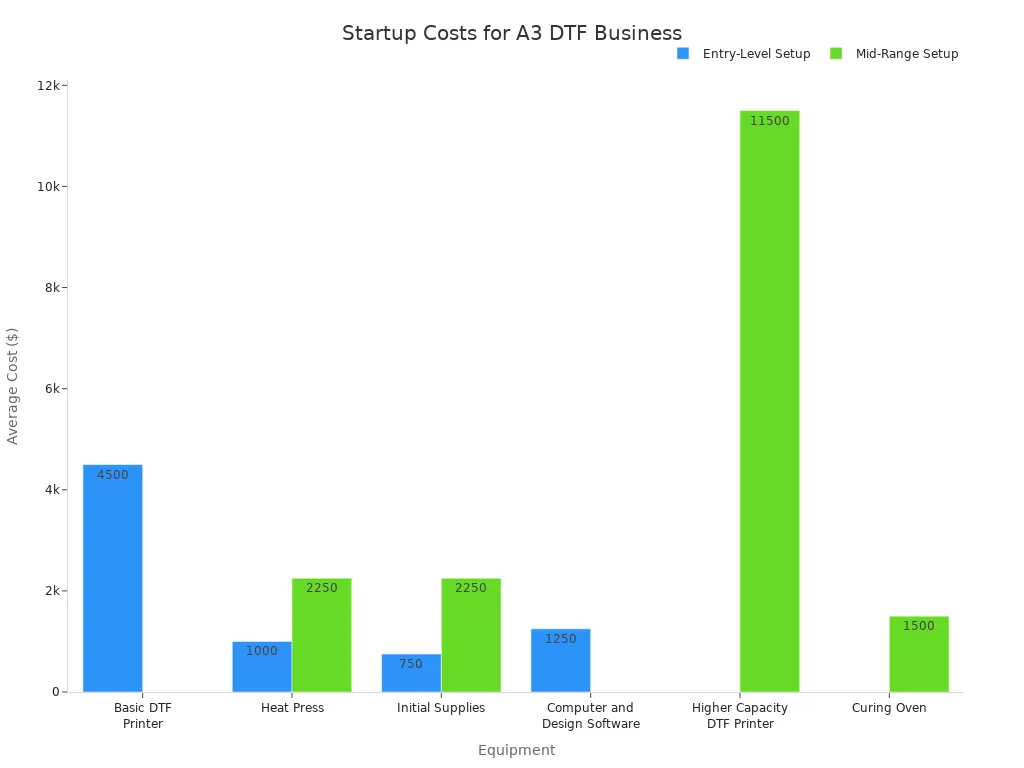

The primary advantage of A3 DTF sheets is the low initial investment. A new business can launch a complete DTF operation for a fraction of the cost of a roll-based system. An entry-level setup, including a printer and heat press, requires a modest capital outlay.

| Equipment | Entry-Level Setup Cost |

|---|---|

| A3 DTF Printer | $2,000 - $3,500 |

| Heat Press | $300 - $600 |

| Initial Supplies | $500 - $1,000 |

| Total Estimated Cost | $2,800 - $5,100 |

This lower financial barrier allows entrepreneurs to enter the custom apparel market with less risk. Furthermore, handling individual sheets is straightforward. Operators can print single designs without wasting material, making a3 dtf pet film ideal for one-off jobs or small, varied batches.

Despite the low entry cost, a3 dtf pet film carries a higher cost per print. Individual sheets are priced between $0.30 and $0.40 each, making them more expensive per square foot than bulk rolls. This higher material cost directly impacts profit margins on larger orders.

Note: As order volume grows, the higher per-unit cost of sheets can quickly diminish profitability compared to the savings offered by rolls.

Production speed is another significant limitation. Printing and curing a single A3 sheet can take anywhere from 2 to 8 minutes, depending on the printer model. This workflow is inefficient for high-volume production. Manually loading each a3 dtf pet film sheet creates a bottleneck that prevents businesses from scaling their output effectively.

DTF film rolls are the definitive choice for established businesses prioritizing production volume and cost reduction. This format is designed for commercial-scale printing, enabling continuous, high-speed operations that are essential for fulfilling large orders and maximizing profitability.

Roll-to-roll systems deliver significant cost savings and operational efficiency. The primary advantage comes from automation. Automated powdering and shaking systems streamline the entire workflow, reducing hands-on work and accelerating turnaround times. This automation offers several key benefits:

It ensures consistent powder application and even heat distribution for flawless adhesion.

It minimizes material waste and keeps the workspace clean.

It allows for uninterrupted production, boosting overall printing output.

Furthermore, rolls allow businesses to use "gang sheets" effectively. Operators can arrange multiple designs on a single continuous sheet, which drastically reduces material waste compared to single-use A3 sheets.

A 24-inch roll provides maximum film coverage. It minimizes waste when printing multiple designs side-by-side, making it perfect for businesses handling many transfers efficiently.

The main drawback of a roll-fed system is the significant initial investment. An entry-level roll-to-roll DTF printer alone can cost between $1,500 and $3,000, with complete systems often exceeding this range. This high upfront cost can be a substantial barrier for new or small-scale operations.

Beyond the financial commitment, operators face a steeper learning curve. Mastering a roll-to-roll system requires technical knowledge to troubleshoot common issues. Operators must learn to manage problems like ink clogging from thicker DTF inks, weak print adhesion due to improper curing, and dull colors resulting from poor-quality supplies. Proper training is essential to prevent costly errors and production delays.

Choosing between sheets and rolls directly impacts a business's financial outlay and operational capacity. A detailed analysis of costs and efficiency reveals a clear trade-off between upfront investment and long-term profitability. This comparison helps businesses align their equipment choice with their financial reality and growth ambitions.

The initial financial barrier is the most significant differentiator between sheet-fed and roll-fed systems. A business can start with an A3 setup for a much lower investment. The printer itself is the main component, with costs varying by business scale.

| Business Type | Printer Size | Suggested Budget |

|---|---|---|

| Small shop or side hustle | A3 DTF Printer | $2,500 – $4,000 |

| Growing business | 24-inch Printer | $5,000 – $9,000 |

Beyond the printer, an A3 workflow requires manual ancillary equipment. A curing oven and powdering tray are essential but relatively inexpensive. A basic A3 curing oven can cost as little as $305, while more advanced models are available for under $900. This keeps the total startup cost manageable for new entrepreneurs.

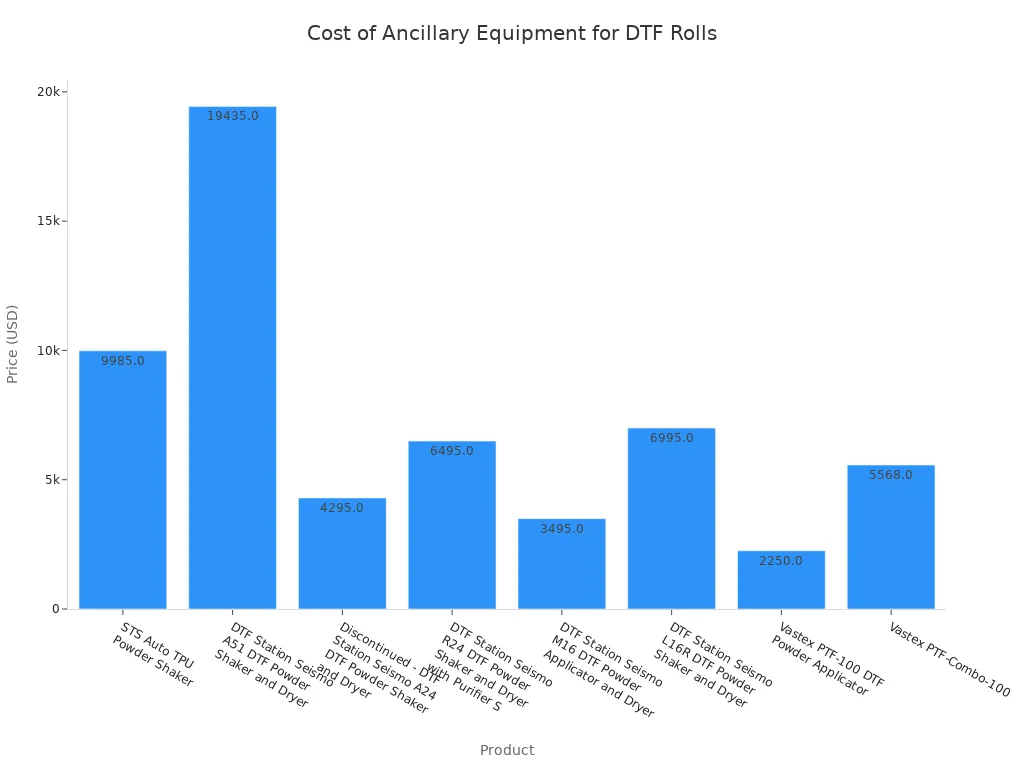

In contrast, a roll-to-roll system demands a substantial capital investment. The printers are more expensive, and the required automated ancillary equipment adds significantly to the total cost. An automatic powder shaker and dryer unit is essential for a continuous workflow, with prices ranging widely.

Entry-level shakers can be found for under $1,000, but high-end commercial systems like the DTF Station Seismo A51 can exceed $19,000. This high upfront cost makes roll-fed systems a choice for established businesses with consistent cash flow.

While A3 sheets offer a lower entry cost, rolls provide superior long-term value through a lower cost per print. The price of bulk film on a roll is significantly less per square inch than individually sold sheets. This difference directly impacts profit margins, especially on large volume orders.

For example, the average DTF printing cost on a roll ranges from $0.02 to $0.10 per square inch. A standard 10x10 inch design (100 square inches) would therefore cost between $2.00 and $10.00 to produce, excluding labor and other overheads.

This cost efficiency is difficult to achieve with a3 dtf pet film, where the fixed price per sheet makes scaling less profitable. As a business grows, the accumulated savings from using rolls can quickly offset the higher initial equipment investment.

The difference in workflow efficiency between sheets and rolls is stark. A manual A3 process is inherently slow and labor-intensive. An operator must print, powder, and cure each sheet individually.

Manual A3 Workflow: An operator spending time coating and curing sheets can only process a few per hour. The curing step alone takes about two minutes per sheet, limiting theoretical maximum output to 30 sheets per hour under ideal conditions. This creates a significant production bottleneck.

Automated Roll Workflow: A roll-to-roll system automates the entire process. The printer feeds the film into a shaker unit that applies powder and cures it continuously. This enables massive gains in output.

High-end commercial systems demonstrate this efficiency clearly. Certain models can process dozens of feet of film per hour, completing printing, powdering, and curing in one seamless operation.

| System | DPI | Pass | Linear Feet/Hour |

|---|---|---|---|

| M&R QUATRO DTF | 720 x 1800 | 6 | 90 |

| M&R QUATRO DTF | 720 x 2400 | 8 | 60 |

Furthermore, rolls enable "ganging" designs—placing multiple jobs onto a single, continuous print run. This practice maximizes film usage and minimizes waste. The workflow for a3 dtf pet film, which requires frequent sheet changes for different designs, cannot match the efficiency of a continuous, ganged print job on a roll.

Selecting the right film format depends entirely on a company's operational scale and business goals. Each model, from a home-based startup to a large commercial factory, has unique needs that either sheets or rolls can meet.

Startups and small online sellers, like those on Etsy, should begin with A3 DTF sheets. This format requires a minimal initial investment, reducing financial risk. Sheets are perfect for creating one-off custom designs and small-batch orders. Their simple, manual workflow is easy for new operators to learn, allowing them to focus on design quality and customer service without the complexity of a large-scale system. 🚀

Growing businesses eventually face a production ceiling with A3 sheets. This is the ideal time to transition to a roll-fed workflow. Roll-to-roll printing offers significant advantages for scaling operations.

It enables continuous printing, which increases production rates.

It overcomes the size limits of sheets, allowing for much longer gang sheet runs.

It improves efficiency by letting operators queue multiple jobs without manual changes. This transition helps a growing shop handle larger orders and improve its profit margins.

Large-scale commercial operations rely exclusively on DTF film rolls. These systems, like the M&R Quatro, are built for high-volume, continuous production. For these businesses, efficiency and cost-per-print are paramount. Roll-fed automation minimizes labor and maximizes output, making it essential for profitability at scale.

“Some will use DTF as a complete business model, where others will use it to take pressure off their other decoration methods,” notes Zac Biberstine of M&R.

This highlights how major operations like Ninja Transfers and STAHLS’ integrate roll-fed DTF printing to either drive their entire business or enhance existing screen-printing workflows.

New businesses should begin with A3 sheets. The low initial cost and simple workflow are ideal for custom one-offs or tight budgets. As order volume grows, a business should transition to DTF rolls. The superior speed and lower cost-per-print directly enhance profitability during expansion.

No, the print quality is identical. The film material is the same. The format only affects workflow, production speed, and cost-per-print, not the final transfer's appearance or durability.

Most roll-fed printers are not designed for sheets. Attempting to use sheets may cause feeding errors and damage the equipment. Operators should always use the film format their printer requires.

Yes, users can arrange multiple small designs on one A3 sheet to save material.

Tip: While possible, rolls are far more efficient for ganging designs. They provide a continuous canvas for queuing many jobs, which maximizes film usage and reduces waste significantly.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Select the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: +86 17706217416

Add: Building L2A, No. 520, Lane 1588, Zhuguang Road, Hongqiao World Center, Qingpu District, Shanghai, China

User Comments

Service Experience Sharing from Real Customers

James Wilson

Print Shop OwnerThe A3 DTF PET film is exceptional. The transfer quality is vibrant and durable, and the film's consistency makes printing and weeding a breeze. Highly recommended for any serious DTF operation.

Sarah Chen

Apparel DesignerAs a small business owner, finding reliable materials is key. This PET film delivers perfect results every time. The prints are sharp, and the film releases cleanly without residue. A game-changer for our custom t-shirt line.

Michael Rodriguez

Production ManagerExcellent film for high-volume DTF transfers. The A3 size is efficient for our workflow, and the PET material is strong and doesn't tear easily. Consistent quality has reduced our waste significantly.

Emily Park

Graphic ArtistI've tried several brands, and this A3 DTF film is by far the best. The color reproduction is accurate, and the final transfer feels soft on fabric. It's become an essential part of my creative business.