DTF Film vs Heat Transfer Vinyl (HTV): Which Is Better for Your Garment Business?

If you run a garment business, you've probably debated: DTF film or HTV? Both work for custom prints, but choosing the wrong one can hike up costs or slow down production. For example, HTV is a nightmare for complex designs—it requires time-consuming cutting and splicing, leading to high waste rates. This guide compares the two across 3 key areas (cost, efficiency, and use cases) to help you pick the right option for your orders. We'll also share real client stories to show how the right choice can save you money.

Cost Comparison

Cost is a make-or-break factor for most businesses—and DTF film wins here by a wide margin:

- Material Cost:

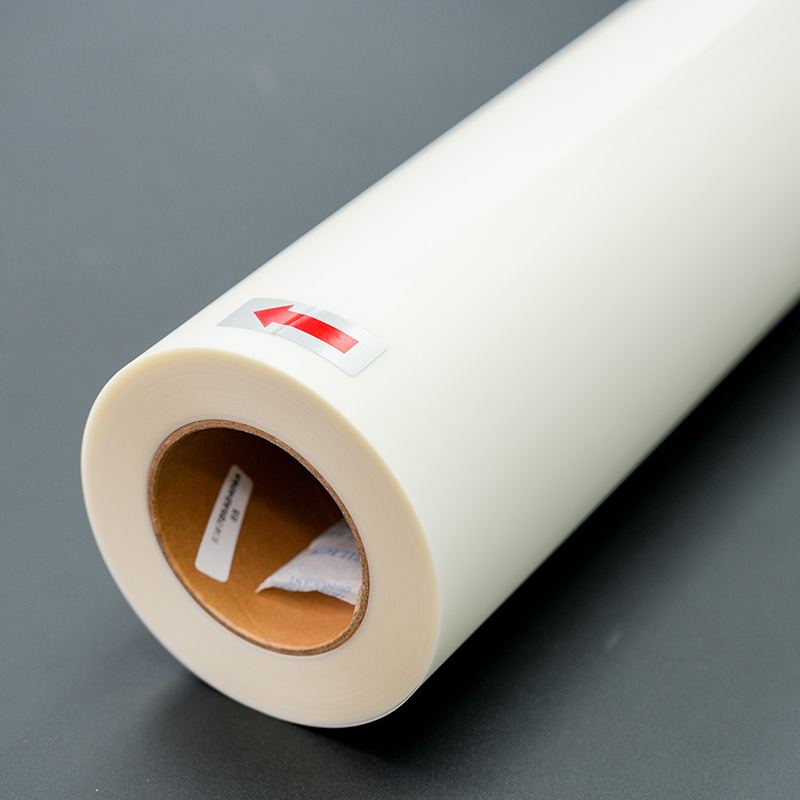

A roll of DTF foil film (60cm × 100m) costs around $28 and can print 500 T-shirts. HTV, by contrast, costs $0.70 per A4 sheet (enough for 1 T-shirt)—that's $350 for 500 shirts. DTF cuts material costs by 25%.

- Labor Cost:

DTF is a 2-step process (print + press) that 1 person can handle for 200 shirts/day. HTV requires cutting each design (30 minutes for complex patterns) before pressing—1 person can only do 50 shirts/day. DTF boosts labor efficiency by 300%.

One of our clients, a custom garment factory, switched from HTV to DTF last year. Their monthly costs dropped from $7,000 to $1,400—a 80% savings—without reducing order volume. For small businesses or startups, this kind of cost cut can mean the difference between profit and loss.

Use Case Comparison

DTF and HTV shine in different scenarios—match the method to your order type:

- Design Complexity:

DTF handles gradients, multi-color logos, and intricate patterns (e.g., cartoon characters) with ease—no cutting needed. HTV requires you to cut each color separately, which leads to misalignment and a 15% waste rate for complex designs.

- Fabric Compatibility:

DTF works on 90% of fabrics, including cotton, polyester, knits, and even canvas. HTV struggles with stretchy knits—our tests show HTV prints on knits crack after 10 washes (60% failure rate), while DTF only has a 5% failure rate.

- Order Volume:

DTF has no minimum order—you can print 1 shirt or 1,000. HTV only makes sense for batches of 500+; small orders waste time on cutting and setup.

For example, a boutique uses DTF for their limited-edition hoodies (10–50 pieces per design) and saves 10+ hours/week compared to HTV. A large sportswear brand, however, uses HTV for their basic logo tees (1,000+ pieces) since the design is simple.

Print Quality Comparison

At the end of the day, your customers care about how the final product feels and lasts—and DTF delivers better results:

- Handfeel:

DTF prints are soft and blend with the fabric. HTV leaves a stiff, rubbery texture that's uncomfortable for everyday wear.

- Durability:

DTF prints withstand 50+ washes without peeling or fading (we test this to meet EU standards). HTV starts to lift at the edges after 20 washes, leading to more returns and unhappy customers.

For premium brands or businesses focused on customer loyalty, DTF's quality advantage is worth it. Even budget-focused businesses benefit—fewer returns mean lower costs in the long run.

Conclusion: Which Should You Choose?

- Choose DTF Film if you:

Print small batches (1–500 pieces), work with complex designs, or use multiple fabric types. It's cheaper, faster, and delivers better quality.

- Choose HTV if you:

Print large batches (500+ pieces) of simple designs (e.g., text logos) on non-stretchy fabrics.

Want to see how much you could save with DTF? Click “WhatsApp” below—we'll calculate your potential cost savings based on your current order volume and send free DTF samples to test.

News & Events

learn more-

Blog

Press Release Nov-25-2025

Blog

Press Release Nov-25-2025Saillage DTF: How to Boost Profit with Wholesale T-Shirt Printing in 2026

For small print shops and creators, 2026 is shaping up to be the year of wholesale t-shirt printing—and at Saillage, we know DTF is the secret to turning this opportunity into real profit. Custom apparel demand is booming: businesses need branded merch, creators launch clothing lines daily, and consumers crave personalized pieces. The key? Bulk printing that cuts costs without sacrificing quality—and our DTF solutions are built to make that happen. -

Blog

Press Release Nov-25-2025

Blog

Press Release Nov-25-2025Saillage DTF Film: Solve Holiday Apparel Headaches & Boost Sales

Whether you’re drowning in Black Friday orders or scrambling for Christmas designs, Saillge DTF film has your back. Below are easy fixes for top holiday struggles—designed to make your work pop, speed up production, and keep customers happy. -

Blog

Press Release Nov-25-2025

Blog

Press Release Nov-25-2025Custom Jerseys, T-Shirts & Hoodies for Teams | SAILLAGE DTF Film

Sports are all about unity—and nothing fuels team pride like custom jerseys, tees, and hoodies that look and feel professional. But creating those standout pieces? It used to mean relying on pricey printers or settling for blurry, generic designs. Enter SAILLAGE DTF Film: the game-changer that lets you craft pro-level team apparel yourself, whether you’re outfitting a youth soccer league or an adult softball crew.

contact us

contact

Tel: +86 17706217416

Add: Building L2A, No. 520, Lane 1588, Zhuguang Road, Hongqiao World Center, Qingpu District, Shanghai, China