products

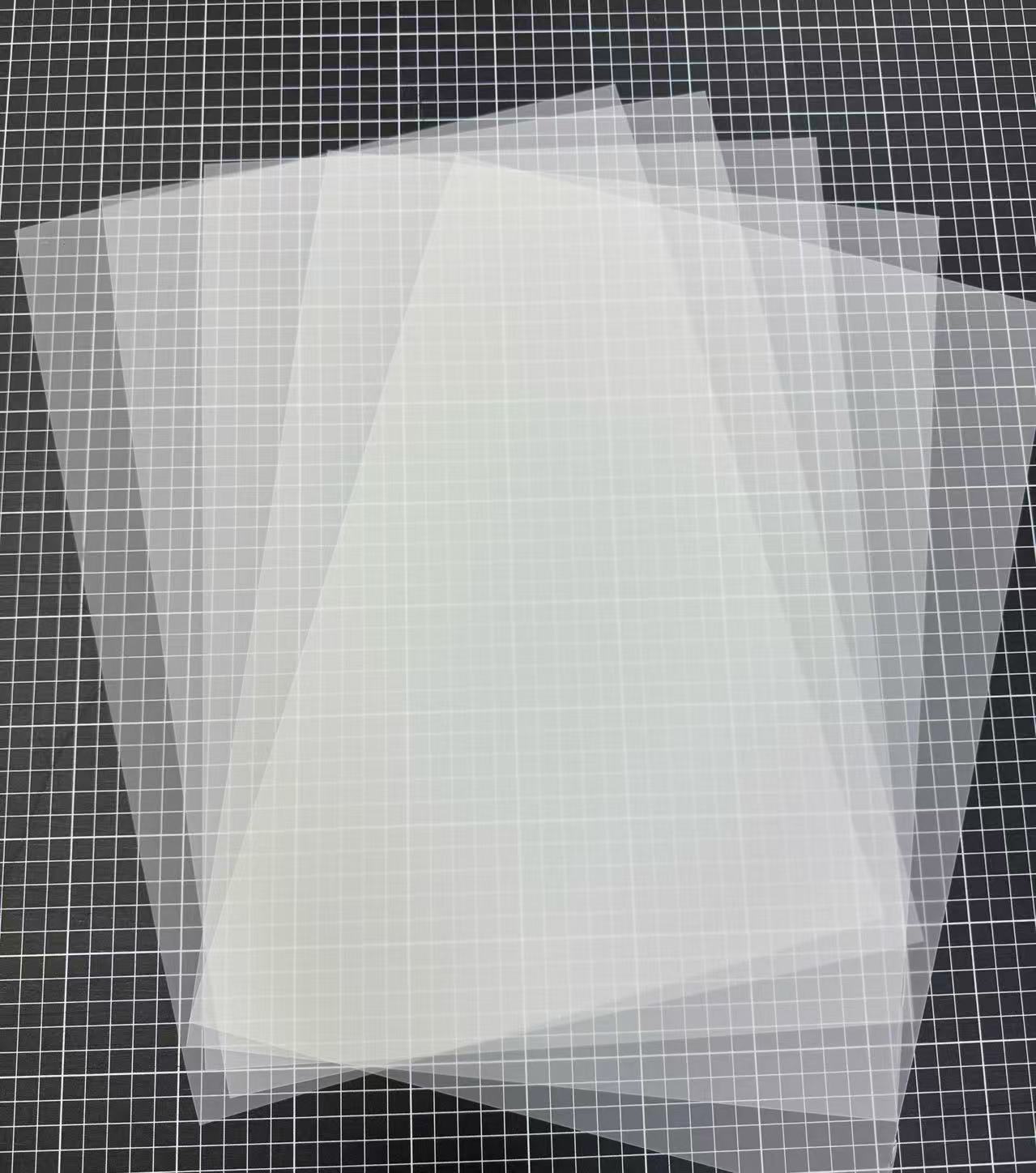

PETG medium shrinkage film TDS

Product Application: Suitable for labeling containers with a significant diameter difference between the neck and the bottle.

-

shrink ratio:

up to 65%

-

Thickness:

20-80μm

-

Liner:

1,32 g/cm³

Technical Specifications:

| Test items | Unit | Typical values | Test method |

|---|---|---|---|

Thickness | μm | 35/40/45/50 | GB/T 6672 |

Thickness deviation | % | ±5 | GB/T 6672 |

Tensile strength at break | MPa | MD ≥ 50;TD ≥ 150 | ASTM D-882 |

Elongation at break | % | MD ≥ 200;TD ≥ 35 | ASTM D-882 |

Heat Shrinkage | % | MD ≤ 40;TD 50–70 | Hot water 90℃/10 s |

Friction coefficient | / | μs ≤ 0.55;μk ≤ 0.55 | ASTM D-1894 |

Haze | % | ≤ 6 | ASTM D-1003 |

45° Gloss | % | ≥ 100 | GB/T 8807 |

Surface Tension | mN/m | No corona treatment surface 38–42;Corona treatment surface 42–54 | ASTM D-2578 |

-

High Shrinkage:

PETG films can achieve impressive shrink ratios, often up to 65%, making them ideal for containers with complex shapes.

-

Clarity and Printability:

PETG films offer excellent transparency and printability, allowing for vibrant graphics and clear visibility of the packaged product.

-

Durability:

They are known for their impact resistance and toughness, providing good protection for the packaged items.

-

Chemical Resistance:

PETG is resistant to oils, alcohols, and many chemicals, making it suitable for a range of products.

-

Food Safety:

It complies with FDA regulations for food contact, making it safe for use in food and beverage packaging.

Technical Specifications:

Become Our Agent

Common Self Adhesive Film Applications

contact us

contact

Tel: +86 17706217416

Add: Building L2A, No. 520, Lane 1588, Zhuguang Road, Hongqiao World Center, Qingpu District, Shanghai, China