A Step-by-Step Guide to Making Direct-to-Film Transfers

Direct-to-Film (DTF) transfers offer a fantastic way to create sharp, detailed prints on various fabrics. If you're looking to dive into this exciting printing method, here's a comprehensive step-by-step guide to help you get started.

Step One: Design Your Artwork

Begin by crafting your design using a graphic design program such as Adobe Photoshop or CorelDRAW. For prints that are crisp and detailed, ensure your design is high-resolution, ideally at least 300 DPI. If your design includes text for DTF, there's typically no need to mirror the artwork. Print in its normal orientation unless your RIP (Raster Image Processor) or DTF film instructions specifically state otherwise.

Step Two: Prepare Your Printer

Whether you're using a converted or dedicated DTF printer, regular maintenance is crucial. This includes white-ink agitation and nozzle checks. Load the PET DTF film (printable matte side) into the feed tray or roll system. Ensure your printer is properly configured with DTF inks, including white ink. If it's a converted printer, flush or prime the lines. Adjust your print quality and resolution settings for optimal results.

Step Three: Set Up the RIP Software

Open the RIP software on your computer. Import your design and fine-tune the settings to achieve the best quality. Pay close attention to color profiles, resolution, and any other printer-specific printing settings.

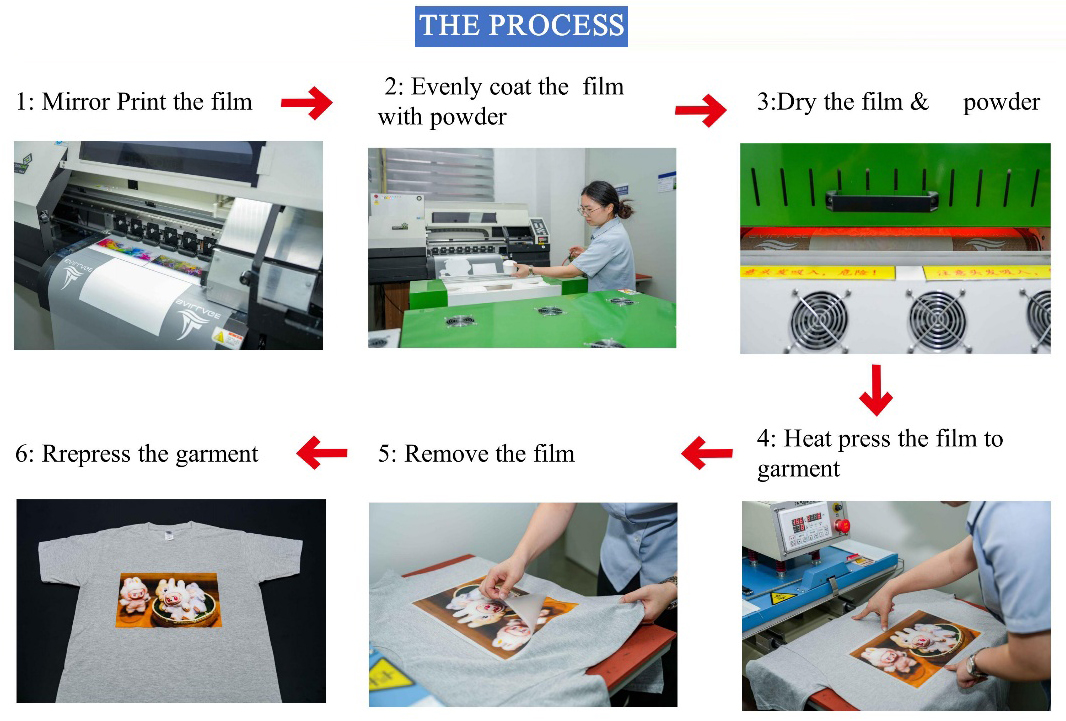

Step Four: Print the Design

Use the RIP software to send your design to the DTF printer. Double-check that the printer settings are correct and print in the normal orientation unless specified otherwise by your RIP or DTF film instructions. This step is vital to ensure the transfer is accurate when applied to the fabric.

Step Five: Apply DTF Powder

While the ink is still wet, evenly spread DTF powder over the printed design. Ensure the entire design is covered to avoid any missed spots. The adhesive powder bonds to the wet ink on the PET DTF film, not directly to the fabric. The dried powder will only bond to the garment when heat-pressed.

Step Six: Curing the DTF Powder

For consistent results, opt for a curing oven or hover press. A heat gun can lead to uneven curing and is not recommended for production. Industry standards suggest controlled curing at around 250–300 °F (120–150 °C) until the powder fully melts. Follow the manufacturer's instructions for time and temperature settings to ensure proper curing.

Step Seven: Prepare the Garment

Set your heat press to the appropriate temperature, typically between 284°F–320°F (140–160°C), depending on your DTF film and ink. Always adhere to the manufacturer's specifications. Place your blank apparel on the heat press and smooth out any wrinkles.

Step Eight: Transfer the Design

Position the DTF transfer film on your cloth, ensuring it's correctly aligned. Use heat-resistant tape to secure the film in place and prevent movement. Press according to your film’s specifications, usually 8-10 seconds for most cold and hot films, with firm, even high pressure of 60 psi or greater.

Step Nine: Peel Off the Film

Peel the film according to its type: hot peel (usually immediately, though some batches may require a few seconds) or cold peel (after fully cooling to room temperature). It's worth noting that you can peel hot peel films as cold peel films. If done correctly, you'll achieve a perfect transfer of the design to your fabric.

Step Ten: Final Touches

If necessary, post-press with a parchment, Kraft, or Teflon sheet for another 9-10 seconds to seal in the designs and enhance durability and hand feel. After 24 hours, wash the fabric to ensure the design is fully set and ready for long-term wear.

By following these steps, you'll be well on your way to creating stunning DTF transfers that will impress and endure. Happy printing!

contact us

contact

Tel: +86 17706217416

Add: Building L2A, No. 520, Lane 1588, Zhuguang Road, Hongqiao World Center, Qingpu District, Shanghai, China