Flexo Printing Explained for Self Adhesive Label Films

Flexo printing uses flexible plates to create high-quality, durable self-adhesive labels. SAILLAGE offers the flexo printing self adhesive label film, which stands out for its print quality and versatility. The table below compares flexo printing to other methods, showing advantages in ink variety, substrate compatibility, and plate durability.

Feature | Flexo Printing | Other Methods |

Ink Variety | More options for VOC considerations | Limited options |

Substrate Compatibility | Wide variety of substrates | Often restricted |

Print Quality | Higher resolution and detail | Varies, often less than flexo |

Durability of Plates | More durable and reusable | Typically less durable |

Flexo printing self adhesive label film Process

Flexo Printing Overview

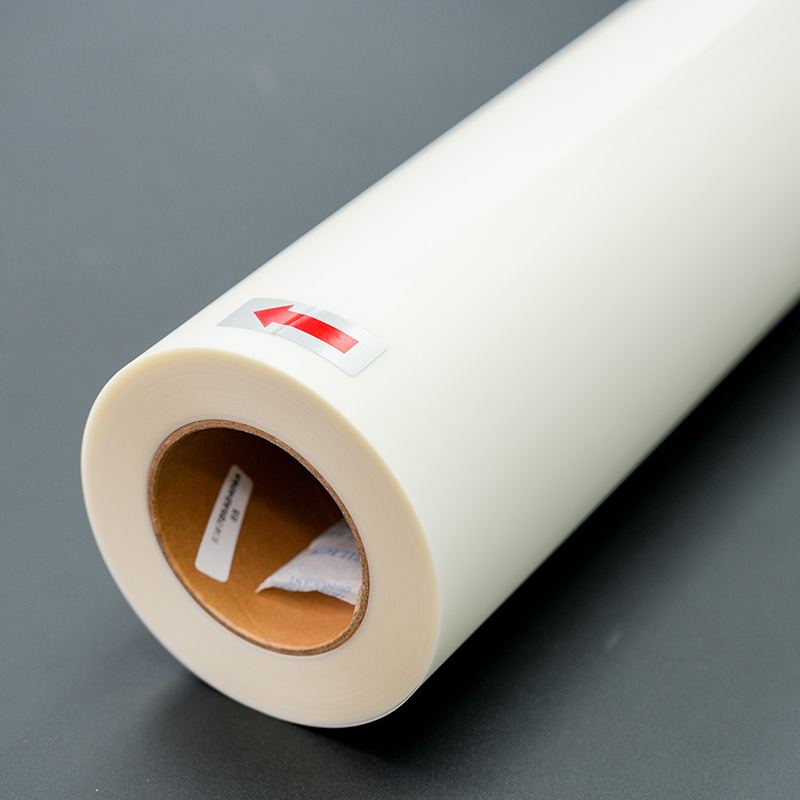

Flexo printing stands as a leading technology for producing high-quality self adhesive label film. This process uses flexible relief plates made from rubber or photopolymer, which transfer ink onto a wide range of substrates. SAILLAGE has advanced this technology by offering flexo printing self adhesive label film solutions that deliver precise ink transfer, vibrant colors, and exceptional durability.

Flexography is a relief printing process that utilizes a flexible rubber or photopolymer plate mounted on a plate cylinder. The printing involves inking the plate image with liquid ink transferred from an anilox roller directly to the substrate using controlled pressure.

Flexographic printing operates on the principle that the image areas on the plate are raised above the non-image areas. Ink is applied to these raised sections, which then press onto the substrate, creating sharp and detailed labels. SAILLAGE’s flexo printing self adhesive label film leverages this principle to produce labels that withstand challenging environments, including moisture, chemicals, and temperature changes.

Flexographic printing on film allows for rapid production speeds and supports up to 8 colors, including spot colors. The process accommodates various ink types, such as water-based and UV-curable inks, enabling custom labels with specific finishes and functionalities. SAILLAGE’s technology ensures that flexo label printing meets the demands of industries like beverages, pharmaceuticals, cosmetics, and packaging.

Key Steps in Flexographic Label Printing

flexo printing self adhesive label film production involves several key steps that guarantee consistent quality and efficiency. The process begins with plate making, where the design is etched onto a flexible plate. Advancements in plate technology, such as flat-top dots, have improved print consistency and detail.

1. The substrate, usually supplied in roll form, enters the flexographic printing press.

2. Ink is applied to an anilox roller, which evenly distributes the correct amount of ink.

3. The inked anilox roller transfers ink onto the flexible plate, etched with the desired design.

4. The plate presses the ink onto the substrate as it passes through the machine.

5. Each color requires its own plate and station, resulting in vibrant and accurate labels.

6. The printed substrate moves through drying or curing systems, such as hot air or UV curing, to ensure proper ink adhesion.

Flexo printing can integrate additional processes, including embossing, laminating, and die-cutting, into a single pass. This integration speeds up production and reduces handling, making flexographic printing on film highly efficient for medium to large volume runs.

· Ink Application: Ink is supplied from an ink pan to the anilox roller.

· Anilox Roller: Distributes a measured amount of ink evenly.

· Printing Plate: Receives ink from the anilox roller.

· Substrate Transfer: The substrate is fed between the printing cylinder and impression cylinder for image transfer.

· Drying/Curing: Systems like hot air or UV curing dry the ink.

Modern flexo printing presses, such as those used by SAILLAGE, operate at high speeds and support advanced ink formulations. Rapid curing under UV light enhances print quality and speeds up production by eliminating drying time. These innovations provide excellent chemical and physical resistance, ensuring that flexo printing self adhesive label film meets industry standards for durability and performance.

Flexographic printing on film often uses eco-friendly acrylic adhesives and facestocks with thermal stability and moisture resistance. SAILLAGE’s flexo printing self adhesive label film supports regulatory compliance for food and pharmaceutical labels, meeting standards such as Regulation (EC) No 1935/2004 and PS 9000. These materials withstand harsh conditions, including low temperatures and exposure to chemicals, making them ideal for beverage, packaging, and cosmetic labels.

Applications and Benefits of Flexographic Label Printing

Common Uses for Flexo Printed Labels

Flexographic label printing serves a wide range of industries. Companies rely on flexo printing to produce labels that meet strict standards for durability and clarity. SAILLAGE’s flexo printing self adhesive label film supports many sectors, including food, beverage, health and beauty, and industrial applications. The table below shows the most common industries using flexo printed self-adhesive label films:

Industry Sector |

Food |

Beverage |

Cannabis |

Health & Beauty |

Nutraceutical & Supplements |

Shipping & Packaging |

Promotional |

Industrial & Chemical |

Flexo printing delivers labels for beverage bottles and cans, providing waterproof and durable branding. Major brands such as Coca-Cola and PepsiCo use flexographic label printing for their packaging. Pharmaceutical companies like Pfizer and Johnson & Johnson depend on flexo for blister packs and tamper-evident labels. Cosmetic brands, including L’Oréal and Unilever, choose flexo for high-quality graphics and precise registration on glossy or textured surfaces.

Sector | Use Case Description |

Beverage | Flexo printing is used for labels on plastic bottles and cans, providing durable, waterproof labels essential for branding. Major brands like Coca-Cola and PepsiCo utilize this technology. |

Pharmaceutical | Used for printing on blister packs and labels, flexo meets strict regulatory standards with precise, legible printing and tamper-evident features. Companies like Pfizer and Johnson & Johnson adopt flexo for their packaging needs. |

Cosmetic | Flexo presses deliver high-quality graphics and precise registration for personal care products, suitable for glossy or textured surfaces. Brands like L’Oréal and Unilever benefit from this technology. |

Flexographic label printing also supports shipping, industrial, and promotional needs. Businesses select flexo printing for its ability to produce labels that withstand moisture, chemicals, and rough handling.

Advantages of Flexo Printing for Self Adhesive Label Films

Flexo printing offers several benefits for self-adhesive label films. Companies value flexographic label printing for its speed, durability, versatility, cost-effectiveness, and print quality.

· Flexographic label printing operates at high press speeds. This efficiency makes flexo printing ideal for large-scale label production. Digital printing works well for short runs, but flexo printing provides the best value for extensive orders with little variation.

· Flexo printing produces highly durable labels. Inks resist wear, water, and UV exposure. Labels remain legible and attractive in outdoor or challenging environments.

· Flexographic label printing accommodates various substrates and ink types. SAILLAGE’s Flexo Printing Self Adhesive Label Film supports water-based, solvent, and UV-curable inks. Brand owners can select the best ink for their specific needs, expanding the range of materials that flexo can print.

· Flexo printing reduces overall production time. Quick setup and rapid production processes allow companies to meet tight deadlines.

· Flexographic label printing delivers superior color precision and image refinement. Brands achieve accurate color matching and enhanced graphics for their labels.

· Flexo printing supports sustainability. Innovations in plate technology and ink formulation reduce waste and align with market trends for eco-friendly packaging.

The table below summarizes the cost-effectiveness and versatility of flexographic label printing:

Evidence Type | Description |

High-Speed Production | Flexographic printing offers high-speed production capabilities, which reduces overall production time. |

Versatility | It can print on various substrates, making it adaptable for different labeling needs. |

Technological Advancements | Innovations like digital flexo technology and improved plates enhance print quality and reduce waste. |

Market Demand | The rising demand for packaged food and beverages increases the need for effective labeling solutions. |

Sustainability Focus | Emphasis on sustainability aligns with market trends, enhancing cost-effectiveness. |

Flexographic label printing provides enhanced print durability, lower cost per impression, and versatility. Companies benefit from improved quality, increased efficiency, and waste reduction.

Why Choose SAILLAGE Flexo Printing Solutions

SAILLAGE stands out as a trusted partner for flexographic label printing. The company offers advanced flexo printing self adhesive label film solutions designed for demanding environments. Our labels feature excellent ink adhesion, water resistance, and chemical durability. These qualities make them suitable for beverage, pharmaceutical, cosmetic, and packaging applications.

SAILLAGE supports customers with expert guidance and responsive service. The team answers common questions about flexo printing, elastomer selection, sleeve care, sustainable printing, and prepress services. We provides clear instructions for maintaining flexo printing equipment, including proper cleaning, storage, and handling of print sleeves and plates.

FAQ

Can SAILLAGE flexo printed labels withstand harsh environments?

Yes. SAILLAGE labels resist water, chemicals, and temperature changes. They remain clear and durable in challenging conditions.

Which industries benefit most from SAILLAGE flexo printed labels?

Beverage, pharmaceutical, cosmetic, and packaging industries use SAILLAGE flexo printed labels for reliable performance and regulatory compliance.

contact us

contact

Tel: +86 17706217416

Add: Building L2A, No. 520, Lane 1588, Zhuguang Road, Hongqiao World Center, Qingpu District, Shanghai, China