How to Use DTF Film: A Step-by-Step Guide for Beginners (2025 Update)

If you’re new to garment printing, using DTF film ...

MoreThe Direct-to-Film (DTF) printing industry demonstrates substantial growth. Market projections highlight this upward trend.

| Metric | Value |

|---|---|

| Market size in 2024 | USD 2.72 billion |

| Market size in 2025 | USD 2.93 billion |

| Projected market size in 2030 | USD 3.92 billion |

| CAGR from 2025 to 2030 | 6.0% |

Professionals need a core set of supplies for success. This checklist outlines the essentials.

Essential Equipment: DTF Printer, Curing Oven, Heat Press, Powder Shaker.

Essential Consumables: DTF Ink, dtf transfer film for sublimation, Adhesive Powder, Maintenance Supplies.

Essential Software: RIP Software.

Selecting the right equipment is the foundation of a successful DTF printing operation. Each machine plays a critical role in the workflow, from initial printing to the final press. This section details the core hardware every professional needs.

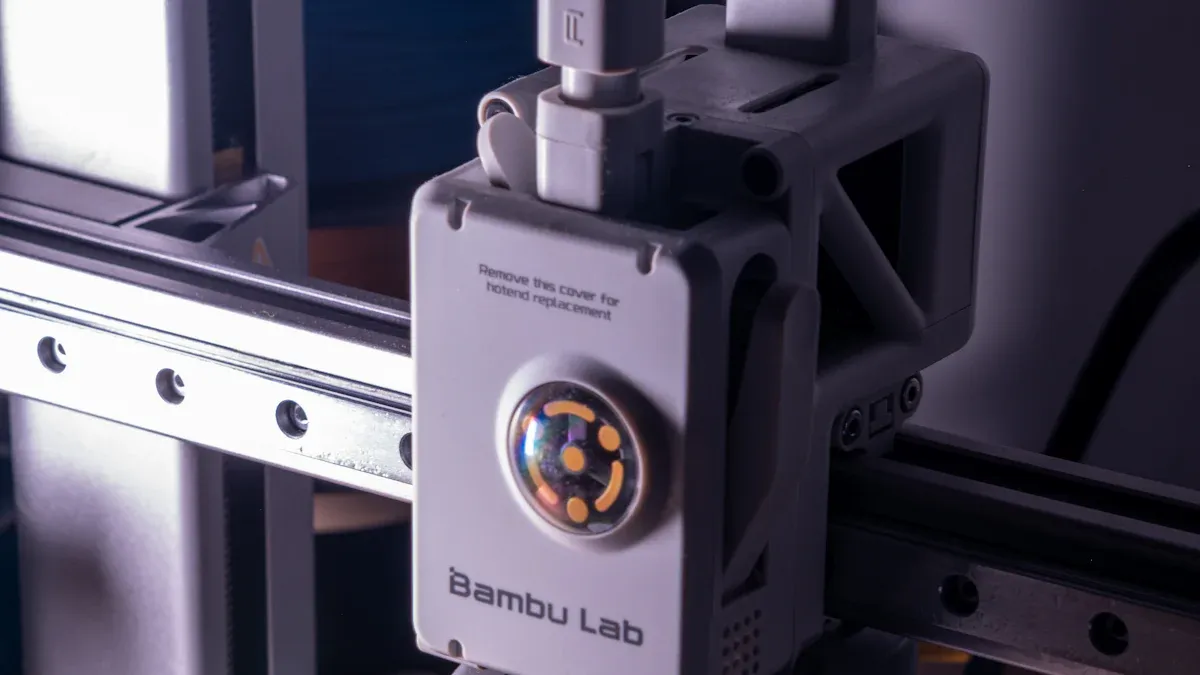

The DTF printer is the heart of the entire setup. It prints the design onto a special transfer film using specialized DTF inks. The quality of the printer directly impacts the final product's detail, color vibrancy, and durability. Businesses must choose a printer that aligns with their production volume, budget, and quality standards.

Printers range from entry-level models, suitable for startups, to professional-grade systems for high-volume industrial use. The initial investment does not always reflect the long-term cost, which includes ink, film, and maintenance.

Printer Comparison: Entry-Level vs. Professional

| Feature/Characteristic | Entry-Level DTF Printers | Professional-Grade DTF Printers |

|---|---|---|

| Affordability | Lower price point, ideal for startups or small-scale production. | Higher cost, caters to high-volume production and industrial applications. |

| Production Scale | Best for low-volume, on-demand jobs. | Designed for continuous, roll-to-roll, and large-batch printing. |

| Speed | Slower print speeds. | Significantly faster, with some systems printing 50 to 300 square feet per hour. |

| Maintenance | Often requires more frequent manual maintenance. | Includes automated features like white ink circulation to reduce clogging. |

For businesses starting out, selecting a model based on projected print volume is a practical approach. The following table offers recommendations for various operational scales.

2026 DTF Printer Recommendations for Small Businesses

| Print Volume | Budget | Maintenance Level | Recommended Model |

|---|---|---|---|

| < 100 prints/month | Under $1,500 | Low | jinlong DTF Mini A4 |

| 100-500 prints/month | $1,500 – $3,000 | Moderate | jinlong DTF Pro L18050 |

| 500+ prints/month | Over $3,000 | High | Prestige R2 Pro |

| High roll-to-roll | $2,500+ | Moderate | STS XPD-724 24” |

After printing and powdering, the adhesive powder on the film must be melted, or "cured." This process creates a uniform adhesive layer that will bond the ink to the fabric. Professionals use either a dedicated curing oven or a heat press for this step.

Curing Ovens are designed specifically for this task. They provide even, consistent heat to cure multiple sheets at once, making them ideal for large batches.

Heat Presses can also cure the powder by hovering the heated platen over the film without direct contact. This method is fast for single sheets but requires careful control.

The choice depends on production volume, space, and budget.

Curing Method Comparison: Heat Press vs. Curing Oven

| Aspect | Heat Press (Hover Method) | Curing Oven |

|---|---|---|

| Efficiency & Speed | Fast for small batches (15-30 seconds per sheet). | Best for large batches, cures multiple sheets at once (2-10 minutes). |

| Quality & Consistency | Good, but requires steady control for even curing. | Excellent uniform heat distribution ensures consistent melting. |

| Cost & Accessibility | More affordable upfront; many shops already own one. | Higher initial investment; suited for professional, high-volume setups. |

| Space & Workflow | Compact and integrates into existing workflows. | Requires dedicated space and ventilation. |

💡 Pro Tip: For consistent results when curing, adhere to recommended settings. However, always perform a test, as factors like film thickness, humidity, and powder type can affect outcomes.

| Setting | Recommended Range |

|---|---|

| Temperature | 320°F to 350°F (approx. 150°C to 177°C) |

| Time | 2-10 minutes, or until the powder appears fully melted and has an "orange peel" texture. |

A heat press machine is non-negotiable. It performs the final, critical step of transferring the cured design from the film onto the garment. The machine uses a combination of high temperature and even pressure to permanently bond the ink and adhesive to the fabric fibers. A high-quality heat press ensures transfers are durable, vibrant, and professional.

Key features separate a hobbyist press from a professional workhorse. Businesses should prioritize machines with:

Digital Temperature and Time Control: Ensures accuracy and consistency for every press.

Even Pressure Distribution: Prevents parts of the design from peeling or washing out.

Appropriate Platen Size: The platen should be larger than the typical design.

Durable Build Quality: A steel frame and a good warranty signify a long-term investment.

The platen size is a crucial consideration. While a 15" x 15" press handles most standard t-shirt designs, a larger 16" x 20" platen offers greater versatility for oversized prints on hoodies or all-over designs.

Recommended Platen Sizes

| Platen Size | Best For | Example Use Case |

|---|---|---|

| 15” x 15” | Small businesses, beginners, standard designs. | T-shirts, tote bags, baby onesies. |

| 16” x 20” | High-volume production, oversized prints. | Hoodies, full-front shirt designs, large back prints. |

Industry experts and users consistently praise certain models for their reliability. Machines like the Geo Knight DK20 series are known as "workhorses" built to last. For businesses scaling up, the Stahls' Hotronix Fusion IQ® offers advanced features like a touchscreen and cloud-based tracking for ultimate control and efficiency.

For high-volume operations, a powder shaker machine is a game-changing investment. This automated unit combines the powdering, powder removal, and curing steps into a single, streamlined process. The printed film feeds from the printer directly into the shaker, where it is evenly coated with adhesive, the excess is shaken off and reclaimed, and the film passes through an integrated oven for curing.

This automation eliminates the messy, time-consuming, and inconsistent nature of manual powdering.

Manual vs. Automatic Powdering

| Feature | Manual Powdering | Automatic Powder Shaker |

|---|---|---|

| Production Volume | Best for low to medium volume. | Ideal for high volume and continuous roll production. |

| Consistency | Depends on operator skill; variation is common. | Guarantees consistent powder distribution and curing. |

| Workflow Efficiency | Slow, labor-intensive process. | Dramatically increases turnaround time and reduces labor. |

| Waste & Mess | Creates airborne powder and material waste. | Enclosed system reduces mess and reclaims unused powder. |

| Cost | Low initial investment. | Higher upfront cost (starting around $1,000-$1,300) but lowers long-term labor costs. |

An automatic shaker directly improves the final product. The uniform powder application creates a stronger bond between the ink and fabric, resulting in prints with enhanced durability that can withstand repeated washing without cracking or fading.

Say goodbye to messy, uneven manual powder application. An automated powder shaker and dryer streamlines the entire workflow. It combines powder coating, curing, and film winding into a single process. Users enjoy consistent, high-quality transfers without the hassle.

High-quality equipment is only half the equation. The consumables and software a business uses directly influence print quality, durability, and operational efficiency. This section explores the essential supplies that transform a design into a finished, sellable product.

DTF inks are specially formulated, water-based pigment inks that form the vibrant core of every print. Unlike standard textile inks, they are designed to print on film first, not directly on fabric. The quality of these inks determines the final transfer's color saturation, detail, and wash resistance.

Professionals prioritize inks that deliver both brilliant colors and long-term durability. Independent tests show that top-tier brands produce prints that can endure numerous wash cycles without fading or cracking. For commercial applications, inks rated for over 40 washes are highly recommended.

DuPont Artistri DTF Inks are known for industrial-grade consistency and can last up to 60 wash cycles. They offer high color saturation and excellent fade resistance.

Epson UltraChrome DTF Inks provide ultra-sharp details and professional color fidelity.

DPI DTF Inks are well-tested for wash resistance, delivering vivid detail and gradation that resists peeling and cracking.

The following table compares the tested durability of several ink brands.

| Brand | Color Vibrancy & Durability Claim | Wash Cycles (Longevity Test) | Fading/Cracking | Notes |

|---|---|---|---|---|

| MTU Tech | Exceptional color vibrancy, durability | 50 | No signs | Top choice for durability |

| Epson | Good color saturation | 30 | Minimal fading | Reliable for moderate use |

| Hiipoo | Decent performance | 20 | Began to fade | Better for short-term projects |

| CMYK | Wide color gamut | 25-40 | Varied | Longevity varies by brand/formulation |

Cost is another key factor. White ink is typically more expensive than colored inks due to its titanium dioxide pigment, which is heavier and requires more advanced formulation to prevent settling.

| Ink Type | Average Cost per Liter |

|---|---|

| White ink | $10-15 |

| Color inks | $5-10 |

The dtf transfer film for sublimation acts as the carrier for the ink and adhesive powder. The printer applies the design to this specialized PET (polyethylene terephthalate) film, which is then coated with powder, cured, and pressed onto the garment. The film's quality affects print detail, ease of release, and the final texture of the transfer.

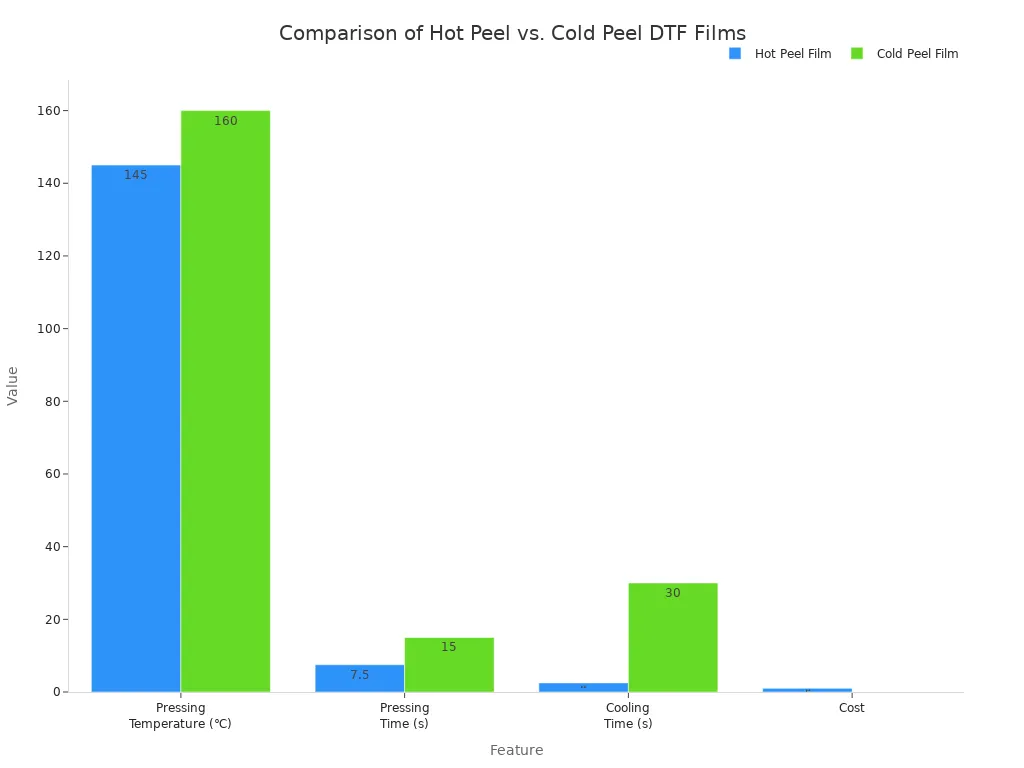

Films are categorized as either hot peel or cold peel, a distinction that dictates the production workflow.

Hot Peel Films allow for immediate peeling after the heat press opens. This significantly speeds up production, making it ideal for high-volume orders of standard designs on fabrics like cotton.

Cold Peel Films require the transfer to cool completely before the film is removed. This slower process allows the adhesive to bond more thoroughly, resulting in sharper details and better performance on intricate designs or special fabrics.

The choice between hot and cold peel dtf transfer film for sublimation depends entirely on the job's requirements for speed versus detail.

| Feature | Hot Peel Film | Cold Peel Film |

|---|---|---|

| Efficiency | Higher (can be torn off almost immediately) | Lower (requires cooling time) |

| Print Quality | Good, but less ideal for fine details | Excellent for complex patterns and small letters |

| Application Materials | Best for common fabrics like cotton | Perfectly suited for special fabrics (canvas, flannelette) |

| Cost | Higher (due to complex production) | Lower |

| Ideal Use | Large volume printing on common fabrics | Intricate designs on a variety of materials |

Several manufacturers, including STS Inks, Chemica US Corp, and DTG PRO, are recognized for producing reliable and consistent dtf transfer film for sublimation.

Environmental Note: Standard PET films contribute to plastic waste. Businesses can make a more sustainable choice by opting for films made from recycled materials or those with certifications like OEKO-TEX®. Proper waste management, including checking with local centers about recycling contaminated PET film, is crucial for reducing environmental impact.

DTF adhesive powder is a hot-melt polyurethane (TPU) powder that functions as the "glue" binding the ink to the fabric. After the design is printed on the dtf transfer film for sublimation, this powder is applied evenly over the wet ink. During the curing stage, it melts into a uniform adhesive layer.

The type of powder used affects the final print's hand-feel, stretchability, and durability. For stretchy fabrics like spandex or polyester blends, a fine-grade TPU powder is essential. Its formulation provides superior abrasion resistance and flexibility, allowing the transfer to stretch with the garment without cracking.

💡 Pro Tip: Proper Powder Storage is CrucialTo prevent clumping and ensure consistent application, store DTF powder in an airtight container in a cool, dry environment. Maintain humidity levels below 50% and a temperature between 65°F to 77°F (18°C to 25°C). Avoid direct sunlight and temperature fluctuations. Using desiccant packets inside the container can help absorb excess moisture.

Skipping preventive maintenance is one of the costliest mistakes in DTF printing. The heavy pigment in DTF inks can quickly cause clogs in printheads and nozzles, leading to banding, wasted materials, and expensive downtime. A structured maintenance routine is non-negotiable.

Common issues like printhead blockage, ink leakage, and inconsistent colors are almost always preventable with daily and weekly care. This requires a dedicated kit of cleaning supplies.

Lint-Free Swabs: For gently cleaning the printhead, wiper blade, and capping station.

Cleaning Solutions: Use solutions specifically formulated for your printer model. Generic cleaners or isopropyl alcohol can damage delicate components.

Syringes: For manually flushing ink lines or printheads as part of a deep clean.

Professionals use different solutions for specific tasks:

Capping Solution: Used for daily wet capping to keep the printhead moist when idle.

Maintenance Solution: Preserves and lubricates printheads during longer periods of inactivity ("vacation mode").

De-Plasticizing Solution: Dissolves solidified ink buildup around the printhead or wiper blade.

Last Chance Solution: A powerful solvent for attempting to clear extremely stubborn clogs.

Following the manufacturer's maintenance schedule and using the correct supplies will extend the printer's lifespan and ensure consistent, high-quality output.

A Raster Image Processor (RIP) is specialized software that translates image files into a format the printer can understand and execute. It is an absolutely essential tool that gives the operator precise control over the final print, far beyond the capabilities of a standard printer driver.

Without RIP software, achieving professional-grade DTF prints is nearly impossible. Its primary functions include:

White Ink Control: RIP software automatically generates and controls the white ink underbase, which is critical for printing vibrant colors on dark garments. It allows users to adjust opacity and choke (slightly shrinking the white layer) for a softer feel.

Color Management: It ensures accurate color reproduction by using ICC profiles to match the colors on the screen to the final printed output.

Gang Sheet Creation: Users can arrange multiple designs onto a single sheet of dtf transfer film for sublimation. This "ganging" feature dramatically minimizes media waste and streamlines production.

Ink Cost Calculation: Many RIP programs estimate ink consumption per job, allowing for accurate pricing and cost control.

Workflow Automation: Features like job queuing and batch processing streamline high-volume workflows, saving significant time and labor.

In short, RIP software optimizes print quality, minimizes waste, and unlocks the full potential of a DTF printer.

A business can launch its DTF operations with a core set of equipment. The initial investment establishes a foundation for professional production.

| Component | Estimated Cost Range |

|---|---|

| Commercial DTF printer | $3,500 – $10,000 |

| Powder shaker & dryer | $1,500 – $5,000 |

| Industrial heat press | $300 – $2,000 |

| Ventilation & setup costs | Varies |

Prioritizing quality supplies ensures professional, durable results. A scalable starter kit, like the InkSonic package, allows a business to grow from a home-based operation into a thriving brand.

Operators can begin with these essentials. They can scale their setup as the business grows, upgrading equipment to meet higher production demands.

No. Standard inkjet printers cannot handle the specialized, thick DTF inks. A dedicated DTF printer is essential for preventing clogs and achieving professional results.

DTF printing works on any fabric color or type, including cotton and darks. Sublimation is limited to light-colored polyester or poly-coated items. DTF uses an adhesive transfer.

High-quality DTF transfers are very durable. They can withstand 40-60 wash cycles or more before showing signs of fading or cracking, often outlasting the garment itself.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

If you’re new to garment printing, using DTF film ...

MoreToday, we’ll break down the core issues, share pra...

MoreSports are all about unity—and nothing fuels team ...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: +86 17706217416

Add: Building L2A, No. 520, Lane 1588, Zhuguang Road, Hongqiao World Center, Qingpu District, Shanghai, China

User Comments

Service Experience Sharing from Real Customers

James Wilson

Print Shop OwnerThis DTF transfer film for sublimation is a game-changer! The color vibrancy and detail on dark fabrics are incredible. It has significantly expanded the product range we can offer to our customers.

Sarah Chen

Product DesignerVery impressed with the ease of use and the sharp results. The film transfers beautifully onto our polyester blends for sportswear samples. A bit more consistency in adhesive would make it perfect.

Michael Rodriguez

Custom Apparel EntrepreneurAs a small business owner, finding reliable materials is key. This DTF film delivers professional, durable prints every time. Customer satisfaction on our personalized t-shirts has gone up since we switched to this.

Lisa Thompson

Production ManagerExcellent product for high-volume orders. The transfer efficiency reduces waste, and the handfeel of the final print is soft. It's now our go-to solution for complex multi-color designs on various substrates.