Valentine’s Day Apparel Crafts: Timeless Wearables Made Easy with DTF Film

Valentine’s Day is all about heartfelt expression,...

MoreThe DTF transfer powder market is highly fragmented, with leading players like STS Inks holding significant share. Industry analysis for 2026 identifies clear front-runners for achieving professional-grade results.

2026 Top Selections:

Top Film: STS Inks Hot-Peel Film offers superior ink absorption and a consistent, clean peel.

Top Powder: Kodak DTF Powder (Medium) provides excellent adhesion and a soft hand feel.

Best Value: A combination of Prestige A3+ Cold Peel inkjet dtf film and X-Coat White Medium Powder delivers high-quality, budget-conscious results.

Selecting the correct inkjet dtf film is foundational to achieving high-quality, durable prints. The film acts as the carrier for the ink and adhesive powder, so its properties directly influence the final product's look, feel, and performance. Factors like peel type, finish, and coating all play a significant role in the production process and final aesthetic.

The most significant decision for any print shop is choosing between hot peel and cold peel film. This choice directly impacts production speed and workflow efficiency. Hot peel film allows for immediate removal after heat pressing, while cold peel film requires a cooling period.

Note: The primary difference lies in the workflow. Hot peel prioritizes speed, whereas cold peel demands patience.

The following table breaks down how each film type affects the production process:

| Feature | Hot Peel Film | Cold Peel Film |

|---|---|---|

| Peeling Time | Immediate, once pressed | Requires cooling until the print is no longer warm |

| Production Speed | Faster, ideal for high-volume orders | Slower, due to the cooling period (30-60 seconds) |

| Workflow Impact | Keeps production lines moving continuously | Creates a bottleneck, demanding careful planning |

| Best For | Rush orders and large-scale production | Small to medium batches where speed is not the priority |

Operators using hot peel film can produce over 100 shirts per hour because there is virtually no downtime between presses. In contrast, cold peel film introduces a mandatory waiting period, slowing the entire operation. This makes hot peel the superior choice for businesses focused on high-volume output and efficiency.

The film's finish determines the final texture and visual impact of the transfer. Each finish offers a distinct aesthetic suitable for different applications.

Matte Film: This film provides a non-reflective, textured finish. It diffuses light, resulting in a soft, satin appearance that is popular for apparel. The colors appear slightly more subdued, lending a professional and understated elegance to the design.

Glossy Film: This film creates a smooth, reflective surface. It enhances color vibrancy and contrast, making designs appear bolder and more saturated. This high-impact finish is excellent for promotional items or designs that need to capture attention.

The choice between matte and glossy often comes down to the desired end result. A matte finish integrates seamlessly into fabric for a soft-hand feel, while a glossy finish provides a polished, photographic look.

DTF films come with either a single-sided or double-sided coating. While single-sided films are common, double-sided options offer distinct advantages, especially in high-volume settings.

A double-sided inkjet dtf film features a coating on both sides. This design provides superior stability during the printing process. The additional coating helps prevent the film from curling or warping as it passes through the printer, reducing the risk of printhead strikes and misfeeds. This enhanced reliability is crucial for maintaining workflow momentum during large production runs. For businesses handling large orders, the improved stability of double-sided film translates to increased productivity and fewer wasted materials.

Ensuring compatibility between the film, ink, and printer is non-negotiable for successful DTF printing. Using the wrong combination will lead to poor adhesion, color inaccuracies, and potential equipment damage.

Most DTF printers require specialized pigment-based inks formulated specifically for the process. These inks contain particles that sit on the film's coating rather than soaking into it. This formulation is essential for creating vibrant, wash-resistant transfers. Standard inkjet pigment inks are not a suitable substitute. They will not bond correctly with the adhesive powder or transfer properly to the fabric.

The table below clarifies the key differences:

| Feature | Specialized DTF Ink | Standard Pigment Ink |

|---|---|---|

| Intended Use | Direct to Film (DTF) printing | Mostly paper printing |

| Adhesion Method | Bonds with adhesive powder | No bonding agent used |

| Substrate Compatibility | Cotton, polyester, blends, and more | Primarily paper; limited on fabric |

| Film Compatibility | Designed for inkjet dtf film | Does not work with DTF film |

Always verify that the ink manufacturer certifies its product for your specific printer model and for use with DTF films. Starting with a sample kit is a wise strategy to test new film and ink combinations before committing to a bulk purchase.

The adhesive powder is the unsung hero of the DTF process. It functions as the "glue" that bonds the printed design to the fabric. Choosing the correct powder is just as critical as selecting the right inkjet dtf film, as it directly determines the final print's durability, texture, and stretchability. A mismatched powder can lead to poor adhesion, a rough hand feel, or cracking after just a few washes.

DTF powders are categorized into grades based on their particle size, measured in microns. Each grade offers distinct properties tailored to specific fabrics and design complexities. The three primary grades are fine, medium, and coarse.

Fine Powder: Best for intricate designs with sharp details. Its small particles create a very soft and flexible finish, making it ideal for lightweight fabrics.

Medium Powder: The most versatile and widely used option. It provides a great balance of adhesion, softness, and durability, making it a reliable choice for general-purpose printing on a wide range of garments.

Coarse Powder: Offers maximum durability and adhesion. Its larger particles create a stronger bond, which is perfect for heavy-duty fabrics like denim, canvas, and workwear that endure significant wear and tear.

The following table provides a clear breakdown of each powder grade and its recommended application.

| DTF Powder Grade | Particle Size (microns) | Best Suited For |

|---|---|---|

| Fine | 50-100 | Smooth, light fabrics; intricate designs; thin, soft prints with fine details |

| Medium | 100-170 | Many types of fabric; general projects; even coverage and steady quality |

| Coarse | 170-300 | Rough or tough fabrics; outdoor items; clothes that get a lot of wear and tear; good adhesion and durability |

While white adhesive powder is the industry standard, black adhesive powder has emerged as a crucial problem-solver for specific applications, particularly with dark garments.

White DTF Powder is the universal choice for most projects. It works effectively on nearly any fabric color and is essential for making colors appear vibrant and opaque. However, when used on dark fabrics, it can sometimes leave a faint white outline around the design if not applied with perfect precision.

Black DTF Powder is specifically formulated to address this issue. It is the ideal choice for dark-themed apparel or designs that need to blend seamlessly into black or navy garments.

It eliminates the risk of a white "halo" effect on dark fabrics.

It enhances the richness of black ink layers, providing superior opacity.

It helps prevent dye migration from the garment into the print.

Black DTF powder is made to stop color migration from bold color garments so it does not show through white ink. This function is critical for maintaining the integrity of light-colored designs on dark-colored polyester fabrics.

The table below compares the primary functions of white and black powders.

| Feature | White DTF Adhesive Powder | Black DTF Adhesive Powder |

|---|---|---|

| Primary Use | High-contrast prints on various fabric colors | Enhancing deep dark colors on dark or colored fabrics |

| Color Saturation | Improves color saturation and vibrancy | Enriches darker shades and enhances print depth |

| Color Interference | Prevents background interference | Prevents faint white edges and dye migration |

| Specific Applications | Professional printing on various films | Dark-themed clothing, designs needing to blend smoothly |

Beyond standard apparel, certain applications demand specialized powders. High-stretch athletic wear is a prime example, as it requires a transfer that can move with the fabric without cracking or peeling.

For sportswear and other performance garments, printers must use a High-Stretch Adhesive Powder.

This powder is made from an advanced thermoplastic polyurethane (TPU) formulation. It creates a flexible, rubber-like bond that stretches and rebounds with the fabric.

Finer particles are essential for these powders. They allow for more effective penetration of the fabric's surface.

The powder must also have a controlled melt viscosity. This ensures it flows properly during curing without over-penetrating and stiffening delicate textiles.

When sourcing supplies for athletic apparel, operators should look for powders specifically marketed as "High-Stretch," "Elastic," or "For Sportswear" to ensure the final product meets performance expectations.

Proper storage and handling of DTF powder are essential for maintaining its quality and ensuring worker safety. Improper conditions can cause clumping, leading to inconsistent application and wasted material.

Storage Conditions 🌡️ Moisture is the primary enemy of DTF powder. To prevent clumping and ensure proper flowability, shops must store their powder in a controlled environment.

Temperature: Maintain a consistent temperature between 65°F and 77°F (18°C to 25°C).

Humidity: Keep relative humidity levels below 60%, with a range of 40-50% being optimal for long-term storage.

Sealing: Always keep powder containers tightly sealed when not in use to protect them from ambient moisture.

Safety and Handling 🧤 DTF powders are fine particulates that can become airborne. Following safety protocols is non-negotiable to protect the health of all staff.

Ventilation: Ensure the workspace has sufficient ventilation, such as exhaust fans or air purifiers, to disperse airborne particles.

Personal Protective Equipment (PPE): Operators must always wear appropriate PPE. This includes masks to prevent inhalation and gloves to avoid skin contact.

Cleanliness: Maintain a clean and organized workspace. Promptly clean up any powder spills to avoid accidental exposure and keep equipment free of residue.

By following these best practices, print shops can maximize the shelf life of their supplies, ensure consistent print quality, and maintain a safe working environment.

Navigating the DTF market requires a strategic balance between supply cost and print quality. While budget options are tempting, premium materials often provide long-term value. Understanding when to invest and how to calculate true costs is essential for profitability.

Investing in premium supplies is justified when performance is non-negotiable. Niche markets like luxury streetwear or performance athletic wear demand superior characteristics. Premium supplies can cost up to 40% more, but they deliver enhanced softness, stretchability, and durability that clients expect. For example, some premium brands guarantee wash resistance for over 60 cycles. UV DTF supplies also fall into this category. Their UV-curable inks offer exceptional colorfastness and crack resistance. While the initial investment is higher, their long-term durability reduces waste and lowers the cost per unit over time.

High-value budget options exist, but they require careful evaluation. Printers should not sacrifice core quality indicators for a lower price. When assessing a budget-friendly inkjet dtf film or powder, key attributes determine its viability.

| Component | Quality Indicator | Description |

|---|---|---|

| Film | Coating & Thickness | A thick, even coating (75-100 μm) ensures vibrant colors and sharp details. |

| Powder | Particle Size | Medium-grade powder (70-170 μm) offers a versatile balance of adhesion and soft hand feel for general use. |

A reliable budget film will have a consistent release layer for smooth peeling, while a good powder will create a durable adhesive layer.

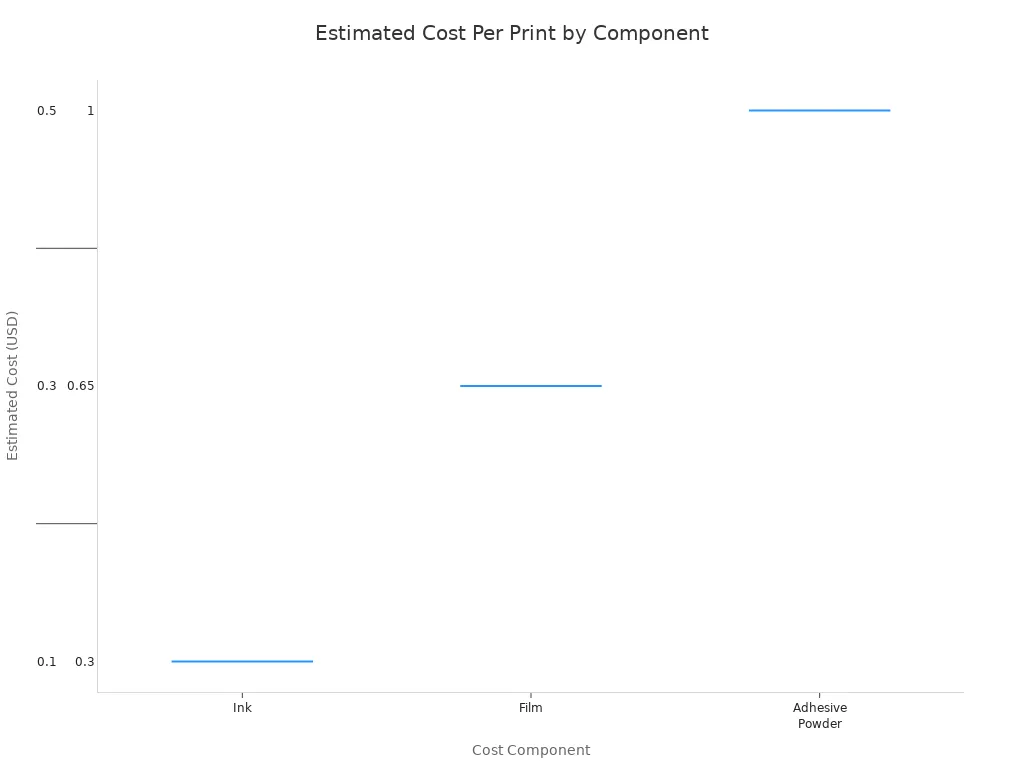

Accurately calculating the cost per print is fundamental to pricing and profitability. This calculation must include all direct and indirect expenses.

Ink: $0.10 - $0.50

Film: $0.30 - $1.00

Adhesive Powder: $0.05 - $0.15

Labor & Utilities: $0.60 - $2.50

Maintenance: $0.05 - $0.30

These figures bring the total estimated cost per print to between $1.10 and $4.45.

Opting for cheap, generic supplies is a false economy. Low-quality materials lead to faded prints, peeling transfers, and equipment malfunctions. These failures damage a brand's reputation and create hidden costs. Professionals often add a 15% "waste factor" to their costs to account for misprints and material failures. Wasted materials, ruined garments, and lost time from troubleshooting quickly erase any initial savings. Investing in a reliable ecosystem of ink, film, and powder is a direct investment in operational peace of mind and long-term success.

Achieving a durable DTF print that withstands washing and stretching depends on precise process control. The interaction between curing, powder application, and material choice directly dictates the final product's longevity and professional finish.

Curing melts the adhesive powder, creating a permanent bond between the ink and the fabric. Incorrect temperature or time settings will compromise this bond. Operators must dial in their settings based on the equipment and materials.

Note: Under-curing results in a sticky feel and poor adhesion, while over-curing can make the ink brittle and prone to cracking.

The ideal curing parameters vary significantly.

| Curing Method | Temperature | Duration |

|---|---|---|

| Heat Press | 320–350°F (160–177°C) | 30–90 seconds |

| Curing Oven | 212–230°F (100–110°C) | 2–3 minutes |

Fine-tuning these settings prevents common failures and ensures a robust transfer.

Consistent powder application is essential for a strong, even adhesive layer. An uneven coating is a primary cause of print failure.

Manual Method: Operators should gently rock the film in a tray to spread powder over the entire design. Flicking the back of the film removes excess particles, preventing a rough texture.

Automated Method: For high-volume production, an automated shaker provides consistent coverage and removes surplus powder efficiently.

Insufficient powder leads to weak bonding and peeling. Too much powder creates stiff "glue spots" that feel rough and can crack when stretched.

Wash testing validates the durability of a DTF transfer. Professional shops often use standards like ISO 105-C06 to confirm quality. Common failures observed during wash tests point to specific process errors.

Cracking and Peeling: This often indicates insufficient heat press pressure or the use of low-quality, expired powder.

Fading: This failure is typically caused by under-curing the transfer, which prevents the ink from properly setting.

Reliable supplies and a dialed-in process are key to passing rigorous wash tests.

A print's ability to stretch with the fabric without damage is crucial, especially for athletic wear. The powder grade directly influences this quality. Standard powders work well on cotton and poly-blends, but high-stretch fabrics like spandex require a specialized high-elasticity TPU powder. This ensures the design moves seamlessly with the garment, preventing cracks and maintaining its integrity through repeated use and stretching.

Buyers can avoid common errors by following a simple checklist.

Your 2026 DTF Buying Checklist:Verify film peel type, powder grade, and printer compatibility before any purchase. Proper powder application ensures a quality finish.

Operators should always prioritize supply quality for durable, vibrant prints. Testing with sample kits is a smart first step.

It allows for quality inspection.

It saves time and resources.

No. Standard printers lack the correct ink system and film handling capabilities. Users need a dedicated or converted DTF printer for reliable, high-quality results.

High-quality DTF prints can endure over 50 washes. Durability depends on premium supplies, correct curing, and proper application, ensuring a long-lasting, professional finish.

Cracking often signals process errors. Common causes include under-curing, incorrect heat press pressure, or using expired or low-quality adhesive powder, which weakens the bond.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Valentine’s Day is all about heartfelt expression,...

MoreWhen it comes to transferring designs onto objects...

MoreIn the packaging industry, two of the most popular...

MoreIn the floral packaging market, BOPP flower wrappi...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: +86 17706217416

Add: Building L2A, No. 520, Lane 1588, Zhuguang Road, Hongqiao World Center, Qingpu District, Shanghai, China

User Comments

Service Experience Sharing from Real Customers

Michael Chen

Print Shop OwnerThis inkjet DTF film is a game-changer for our custom apparel business. The transfer quality is incredibly vibrant and the film is very consistent, with no curling or jamming in our printers. Highly recommended!

Sarah Johnson

Graphic DesignerAs a designer, color accuracy is everything. This film delivers perfect color reproduction and fine detail on dark fabrics. The ease of use has significantly sped up our production workflow. Excellent product.

David Rodriguez

Production ManagerVery reliable film for high-volume orders. The adhesion is strong and the prints are durable after washing. We've reduced our waste rate since switching to this brand. One point off as the packaging could be sturdier for shipping.

Emily Watson

Small Business OwnerStarting a small DTF printing side hustle, and this film made the learning curve much smoother. It's forgiving, produces professional results, and the price is great for starters. Customer service was also very helpful.