Top 10 China Suppliers of Substrate BOPP Films (2026)

China is one of the world’s largest producers of B...

MoreThe dtf powder and film system is foundational to this printing process. The powder, a Thermoplastic Polyurethane (TPU) hot-melt adhesive, acts as the glue bonding designs to fabric. The film is a special carrier sheet holding everything together before pressing. This technology drives a rapidly expanding global market.

2024 Market Size: USD 2.72 billion

2030 Projection: USD 3.92 billion

The dtf powder and film system operates through a precise, two-part process. The film provides the foundation, and the powder creates the bond. Each component performs a distinct but complementary function to achieve a high-quality final print.

The DTF film acts as a temporary base for the printed design. A printer applies specialized DTF inks directly onto this Polyethylene Terephthalate (PET) sheet. The film’s unique coating holds the wet ink in a sharp, detailed layer without letting it bleed. Films come in two main types, hot peel and cold peel, which determine when the film is removed after heat pressing.

| Feature | Hot Peel DTF Film | Cold Peel DTF Film |

|---|---|---|

| Peeling Method | Detached while hot, immediately after pressing. | Detached after cooling completely. |

| Efficiency | Faster, ideal for high-volume production. | Slower, suitable for custom prints. |

| Wash Durability | Good, but can bond aggressively to uneven fabrics. | Often superior, with less cracking over time. |

The DTF powder is the essential binding agent. It is the "glue" that permanently attaches the ink to the fabric. The process is straightforward:

Print Your Design: A printer first prints the design onto the PET transfer film.

Apply the Powder: While the ink is wet, an operator sprinkles the powder evenly over the entire design.

Shake Off Excess: The operator then shakes the film to remove any loose powder.

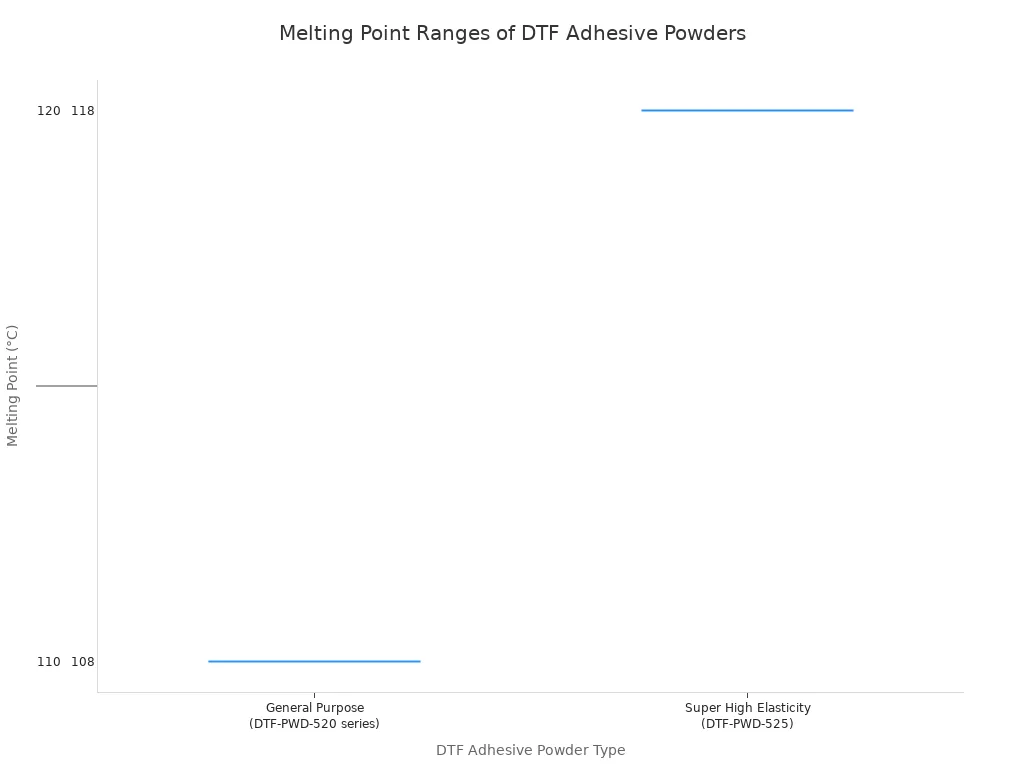

Cure the Powder: The film is heated briefly (around 100–120°C), which melts the powder onto the ink.

Transfer to Fabric: Finally, the film is pressed onto the garment at a higher temperature (160–170°C) to complete the transfer.

The powder's particle size also affects the final texture. Finer powders create a softer feel, while coarser powders offer maximum durability for items like work jackets. The melting point of the dtf powder and film is also critical, as different powders are designed for specific fabrics and applications.

The synergy between DTF powder and film is not just a procedural step; it is the core of the entire printing method. These two components work in perfect harmony to transform a digital design into a tangible, wearable piece of art. Their combined function is critical for achieving durability, color vibrancy, and print precision.

The primary function of the dtf powder and film system is to create a permanent bond between the ink and the fabric. The process relies on a few key scientific principles.

Heat-Activated Adhesion: The powder melts under heat, fusing with the ink and the garment's fibers. This creates a unified layer that is both flexible and strong.

Material Compatibility: The system uses water-based inks and a TPU powder adhesive. Their chemical compatibility ensures they bond correctly for a long-lasting print.

Transfer Medium: The film acts as the perfect carrier. It holds the design until the heat press activates the powder, facilitating a complete transfer.

This powerful bond results in impressive durability. A properly applied DTF transfer can withstand 50 to 100 wash cycles before showing significant wear. Some tests show high-quality prints lasting over 50 washes with no fading. The tensile strength of a cured TPU adhesive bond can exceed 250 kg/cm², demonstrating its exceptional resilience to stretching and pulling.

Pro Tip: Maximize Print LongevityTo get the most out of your DTF garments, follow these simple care instructions. Following these steps helps prevent common issues like cracking, fading, or weakening adhesive.

Washing: Turn the garment inside out and use a gentle cycle with cold water and a mild detergent. Avoid bleach.

Drying: Air drying is best. If using a machine, choose the lowest heat setting. Avoid fabric softeners.

Ironing: Never iron directly on the print. Turn the garment inside out or use a pressing cloth on a low heat setting.

The quality of the final print's color depends heavily on the interaction between the powder and the film. The powder itself, composed of TPU resin and pigments, directly influences color performance. The film’s special release coating is equally important, ensuring all the ink transfers without leaving any residue behind. This clean separation is vital for maintaining the design's intended vibrancy.

The choice between white and black DTF powder also plays a strategic role in color output. Each is designed for specific fabric colors to maximize saturation and visual impact.

| DTF Powder Type | Recommended Fabric | Impact on Color |

|---|---|---|

| White Powder | Light-colored fabrics | Creates a bright base, enhancing color saturation and preventing the fabric color from showing through. |

| Black Powder | Dark-colored fabrics | Prevents dye migration from the fabric, boosting the richness and vibrancy of the printed colors. |

Using black powder on dark fabrics like navy or black polyester is especially effective. It acts as a barrier, ensuring the design's colors appear vivid and true, rather than muted by the dark background.

Precision is a hallmark of high-quality DTF printing. The film holds the ink in crisp, well-defined shapes, preventing any bleeding before the powder is applied. This allows for the reproduction of incredibly fine details. However, there are physical limits to this precision.

For reliable results, design elements and lines should have a minimum thickness of 0.018 to 0.02 inches (around 0.5 mm). Lines thinner than this may not hold enough ink and powder, compromising the print's durability and washability after transfer.

Improper use of the powder or poor-quality materials can lead to several transfer defects. Common issues include:

Powder Clumping: High humidity can cause the powder to clump, leading to an uneven texture.

Incomplete Adhesion: Applying too little powder or using low-quality materials can cause the print to peel.

Loss of Vibrancy: Incorrect curing temperatures or a poor-quality film can make colors appear dull.

Ultimately, the teamwork between the powder and film is essential. The film provides the perfect canvas, and the powder provides the powerful glue. Together, they ensure every detail of the design is transferred cleanly and permanently.

The dtf powder and film system is a partnership. The film carries the design, and the powder acts as the essential adhesive that makes the transfer permanent. Without the powder, the ink will not stick; without the film, there is no way to transfer the design. Their teamwork is the foundation for creating durable and vibrant custom apparel.

Store materials in a cool, dry environment with low humidity (below 50% RH). Keep them sealed in their original packaging to prevent moisture absorption and maintain quality.

Most powders and films are compatible. However, using a matched system from a single supplier often yields the best results. High-quality materials ensure consistent adhesion and color vibrancy.

This issue often happens if the ink is too dry or applied too thinly. Ensure your printer settings provide adequate ink coverage. Using old or low-quality ink can also cause poor adhesion.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

China is one of the world’s largest producers of B...

MoreDTF films deliver excellent performance when prope...

MoreIn 2026, new EU environmental regulations are resh...

MoreIf you run a garment business, you’ve probably deb...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: +86 17706217416

Add: Building L2A, No. 520, Lane 1588, Zhuguang Road, Hongqiao World Center, Qingpu District, Shanghai, China

User Comments

Service Experience Sharing from Real Customers

Michael Rodriguez

Graphic DesignerThe DTF powder and film combo is a game-changer for my custom apparel projects. The color vibrancy after curing is exceptional, and the transfer feels durable and soft on fabric. Highly recommended for detailed designs.

Sarah Chen

Print Shop OwnerExcellent product consistency. The DTF powder adheres perfectly with the film, resulting in minimal waste and crisp transfers. It has significantly sped up our production line for promotional merchandise.

David Kim

Production ManagerAs someone in charge of textile manufacturing, I appreciate the reliability of this DTF system. The powder melts evenly, bonding the film securely to various fabrics without cracking or peeling. A top-tier industrial solution.

Jessica Williams

Small Business OwnerStarting my own custom gift shop was made easier with this DTF powder and film. The learning curve was small, and the professional results impress my customers every time. The durability on mugs and textiles is outstanding.