How to Convert Plain BOPP Film into Woven Bags

Introduction to BOPP Laminated Woven Bags

In the industrial and agricultural packaging sectors, woven bags laminated with BOPP film are widely used for their strength, durability, and attractive appearance. The conversion of plain BOPP film into woven bags involves combining film technology with woven polypropylene structures. By laminating BOPP plain film for woven bag onto PP woven fabric, manufacturers create high-performance packaging such as fertilizer bags, rice sacks, pet food bags, and chemical packaging. Understanding this process helps ensure consistent quality and reliable performance of PP woven sack laminated BOPP film products.

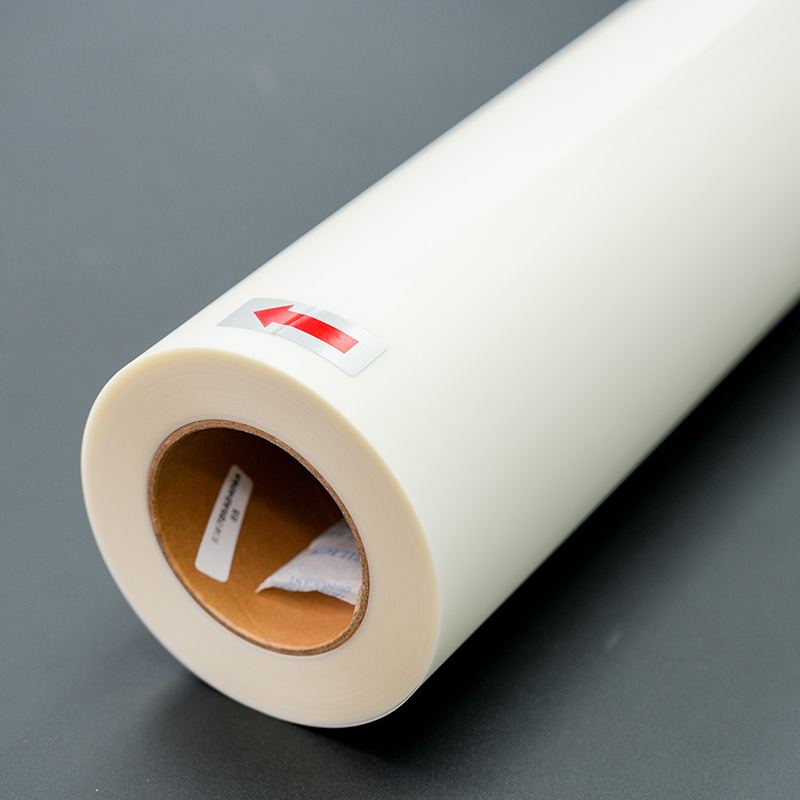

Selecting Suitable Plain BOPP Film

The first step in producing laminated woven bags is selecting the right plain BOPP film. High-quality BOPP film should offer excellent tensile strength, uniform thickness, and stable surface properties. When used as BOPP plain film for woven bag, the film must withstand lamination heat and tension without shrinking or wrinkling. Consistency in plain BOPP film quality is critical for achieving strong adhesion in PP woven sack laminated BOPP film structures.

Printing on Plain BOPP Film

To create visually appealing woven bags, plain BOPP film is typically printed before lamination. Flexographic or gravure printing methods are commonly used to apply logos, product information, and branding. Proper surface treatment ensures good ink adhesion on BOPP plain film for woven bag. High-quality printing enhances the commercial value of PP woven sack laminated BOPP film, making the bags more competitive in the market.

Lamination with PP Woven Fabric

The core converting step is lamination. During this process, plain BOPP film is bonded to PP woven fabric using extrusion lamination or adhesive lamination techniques. Molten polypropylene or adhesive acts as the bonding layer, creating strong adhesion between the film and the woven substrate. This step transforms BOPP plain film for woven bag into durable PP woven sack laminated BOPP film, combining the stiffness and print quality of BOPP film with the strength of woven fabric.

Cutting, Sewing, and Bag Making

After lamination, the PP woven sack laminated BOPP film rolls are cut into specific sizes. The laminated material is then formed into bags through folding, sewing, or ultrasonic sealing. Features such as gussets, valve openings, and reinforced bottoms can be added depending on the application. Throughout this stage, the integrity of the plain BOPP film layer must be maintained to ensure print quality and durability of the final woven bags.

Quality Control and Performance Testing

Quality control is essential when converting plain BOPP film into woven bags. Tests are conducted to evaluate adhesion strength, print durability, tensile performance, and resistance to moisture and abrasion. These tests ensure that BOPP plain film for woven bag meets customer specifications and performs reliably in real-world use. Consistent quality control guarantees the long-term performance of PP woven sack laminated BOPP film packaging.

Conclusion

Converting plain BOPP film into woven bags is a structured process that includes film selection, printing, lamination, and bag making. By using high-quality BOPP plain film for woven bag and precise lamination techniques, manufacturers can produce durable, attractive PP woven sack laminated BOPP film products. These laminated woven bags offer excellent strength, visual appeal, and protection, making them ideal for a wide range of industrial and agricultural packaging applications.

News & Events

learn more-

Blog

Press Release Feb-06-2026

Blog

Press Release Feb-06-2026Valentine’s Day Apparel Crafts: Timeless Wearables Made Easy with DTF Film

Valentine’s Day is all about heartfelt expression, but too many seasonal crafts end up tucked away in drawers once February fades. For brands and crafters hoping to create memorable Valentine’s apparel that feels special beyond the holiday, DTF film (direct-to-film transfer film) is the game-changing solution. It turns simple Valentine’s themes into wearable, timeless designs that transcend the holiday, making every piece feel intentional, versatile, and worth wearing year-round. -

Blog

Press Release Feb-06-2026

Blog

Press Release Feb-06-2026What's The General Applications Of Double-Side Matte Bopp Film

In the flexible packaging and graphic materials market, double-side matte BOPP film has gained strong popularity due to its refined appearance and functional surface properties. Unlike glossy films, Both Side Matt BOPP Film offers a soft, low-reflection finish on both sides, creating a premium visual and tactile experience. As a specialized form of BOPP matt film, BOPP double-sided matte film is widely used in applications where elegance, readability, and controlled light reflection are required. -

Blog

Press Release Feb-06-2026

Blog

Press Release Feb-06-2026Essential Long-Term Storage Guidelines for DTF Film

DTF films deliver excellent performance when properly maintained, and storage methods play a key role in preserving their adhesive strength, image clarity, and overall pressing effect. With scientific storage and flawless heat settings, you can consistently achieve strong bonding, vivid prints, and smooth edges for every application.

contact us

contact

Tel: +86 17706217416

Add: Building L2A, No. 520, Lane 1588, Zhuguang Road, Hongqiao World Center, Qingpu District, Shanghai, China