A Step-by-Step Guide to Making Direct-to-Film Transfers

Direct-to-Film (DTF) transfers offer a fantastic w...

MoreDirect-to-Film (DTF) technology prints detailed designs onto a special clear film. An adhesive powder then coats the wet ink and cures with heat. This process creates a ready-to-apply dtf clear film transfer for heat pressing onto garments, celebrated for its durability and fabric versatility.

The global DTF printing market is projected to be valued at $667 million in 2025, highlighting its significant industry impact.

Industry experts position DTF as a dominant force in decorated apparel for 2025. Analysts like Johnny Shell from Keypoint Intelligence and authors like Frank Smith note that DTF is "leading the way" by delivering sharper colors and long-lasting prints. This technology has become a popular choice for businesses because it solves many challenges found in other printing methods. Its primary advantages lie in fabric compatibility, color vibrancy, durability, and cost-efficiency.

One of the most significant benefits of DTF printing is its ability to work with an extensive range of materials. Unlike methods limited to specific fabric types, DTF adheres to:

100% Cotton

Polyester

Cotton/Poly Blends

Nylon

Leather

Treated wood and other hard surfaces

This adaptability gives creators immense freedom. A dtf clear film transfer applies just as well to a cotton t-shirt as it does to a polyester sports jersey. It even opens doors for customizing unconventional items. For example, many businesses successfully apply DTF to challenging materials by adjusting their process.

Pro Tip: Applying DTF to Special Materials

Nylon: Use a lower temperature (around 265°F) with light pressure and a protective silicone sheet. This helps the transfer adhere without damaging the heat-sensitive fabric.

Leather: Clean the surface with isopropyl alcohol to remove oils. This pre-treatment ensures a strong bond between the adhesive and the material.

DTF technology excels at producing brilliant, high-fidelity colors on any garment shade. This is possible because every design is printed with a white ink underbase. This opaque white layer acts as a primer, ensuring the colored inks on top appear bright and true to the original design, even on black or dark-colored fabrics.

The DTF process uses an expanded ink set that often includes not just CMYK (Cyan, Magenta, Yellow, Black) but also red, green, blue, and orange inks. This wider color gamut allows for more accurate and vivid reproductions compared to standard printing methods.

| Printing Method | Vibrancy Strengths |

|---|---|

| Standard CMYK | Detailed, natural tonal range |

| DTF | Extremely vibrant, high detail on all colors |

The science behind this vibrancy lies in the ink's composition. DTF inks use ultra-fine pigments, including titanium dioxide for the opaque white base, suspended in a liquid carrier. These pigments, combined with polyurethane binders, ensure the ink adheres strongly while remaining flexible.

Note: Achieving maximum vibrancy depends on proper curing. Under-cured inks can appear dull, while over-curing may cause color shifts. Following manufacturer guidelines for heat and time is essential for optimal results.

A high-quality dtf clear film transfer is built to last. The cured ink and adhesive form a permanent bond with the fabric's fibers. As a result, finished garments can typically withstand 50 to 100 wash cycles without significant fading, cracking, or peeling.

| Test Aspect | Result (Washes) | Condition After Washes |

|---|---|---|

| Black DTF Prints (Fading) | ~52 | Still looking fresh, no fading |

| DTF Transfer Shirts (Cracking/Peeling) | ~20 | No cracking or peeling |

Beyond washability, DTF also offers impressive stretchability, making it suitable for performance wear and fabrics with spandex. The elasticity of the final print depends on using a complete system of flexible materials. To achieve great results on stretchy garments, printers must use:

Stretchable DTF Films: These films are designed to move with the fabric.

Flexible Inks: Inks formulated with elastic properties prevent cracking when stretched.

Soft Adhesive Powders: A softer powder creates a bond that can flex without breaking.

When these components work together, the dtf clear film transfer moves with the fabric, maintaining design integrity and comfort for the wearer.

DTF printing eliminates many of the setup costs associated with traditional methods like screen printing. There are no screens to create or multiple colors to register. This makes it highly cost-effective for small to medium-sized orders, as the cost-per-print remains low and consistent. For batches of 50-100 units, DTF is often more affordable than screen printing.

| Printing Method | Cost Per Piece (50-100 units) |

|---|---|

| DTF | $1.05 - $1.95 |

| Screen Printing | $1.50 - $2.80 |

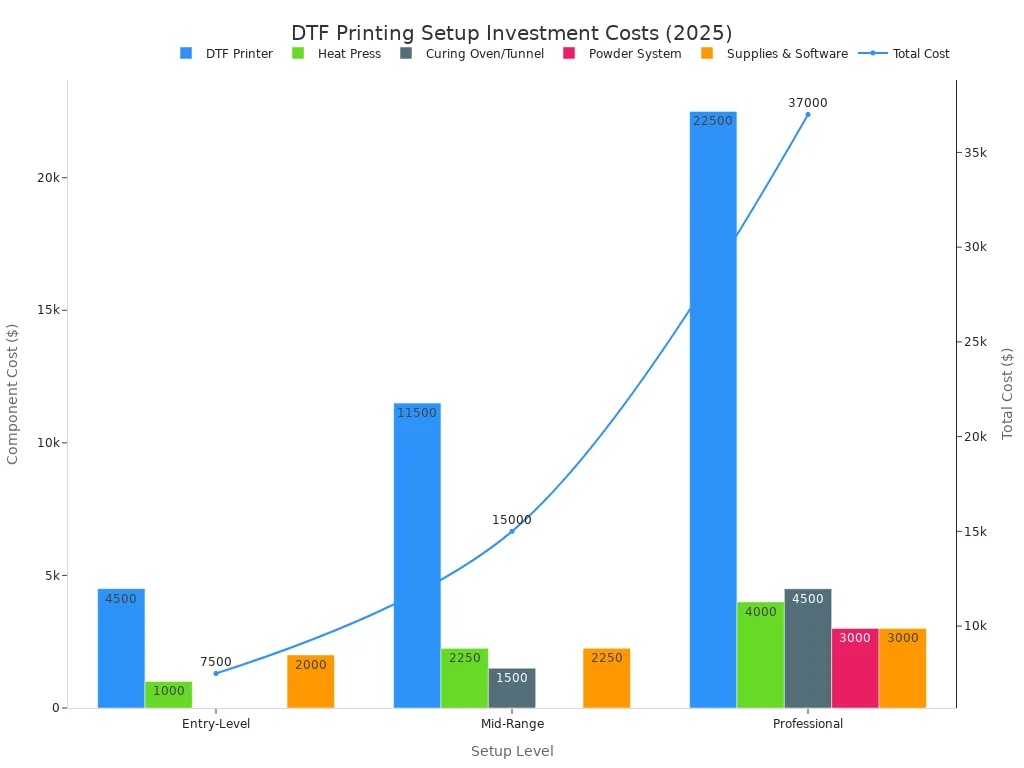

While the operational costs are low, setting up a DTF printing system requires an initial equipment investment. Costs can range from $5,000 for an entry-level setup to over $20,000 for a professional-grade system.

This investment gives businesses the ability to produce on-demand, full-color prints for a wide variety of customers without the high setup fees of other methods.

Understanding the DTF workflow and its advantages over other methods is key to leveraging its full potential. The process is straightforward, and its benefits become clear when compared to traditional decoration techniques.

The DTF process transforms a digital design into a durable garment graphic in a few key stages.

Printing: A specialized DTF printer prints the design onto a clear PET film, starting with the color layer and finishing with a white ink underbase.

Powdering: The wet print is coated with a thermoplastic adhesive powder.

Curing: The film is heated in a curing oven or with a heat press at around 230-250°F. This melts the powder, creating a smooth adhesive layer.

Pressing: The finished dtf clear film transfer is heat-pressed onto the garment, permanently bonding the design to the fabric.

DTF holds a significant advantage over DTG in its workflow. DTG printing requires a mandatory fabric pretreatment step to ensure ink adhesion, which adds time and cost. DTF completely eliminates this step. While DTG prints offer a softer feel by soaking into the fabric, DTF prints sit on top and have a smooth, slightly thicker texture.

Fabric versatility is the primary difference here. Sublimation only works on light-colored polyester fabrics because the ink dyes the fibers directly. This process results in zero hand-feel. DTF, however, applies to nearly any fabric type or color, including cotton and dark garments, by placing a tangible layer on the material's surface.

DTF excels where screen printing becomes complex. It handles full-color, detailed graphics without the extensive setup of creating multiple screens, making it ideal for smaller, intricate orders.

DTF streamlines the production of complex graphics. HTV requires a tedious weeding process to remove excess vinyl, which is time-consuming for intricate designs. DTF has no weeding. Furthermore, DTF prints are generally more durable and flexible than multi-layered HTV designs, which can feel stiff and risk peeling after repeated washes.

DTF clear film transfers merge versatility, vibrancy, and durability into one powerful solution. This method overcomes key limitations found in traditional printing, making it ideal for the custom apparel market in 2025. For businesses requiring high-detail designs on any fabric or color, DTF technology remains a leading contender.

A quality DTF transfer withstands 50 to 100 wash cycles. It resists cracking and fading, ensuring long-term design integrity on the garment.

Yes, a DTF print has a tangible feel. The design sits on the fabric's surface, creating a smooth, slightly raised texture unlike ink-dyed methods.

A basic DTF setup requires specific equipment. Key components include:

Specialized inks and film

A curing unit

A heat press

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Direct-to-Film (DTF) transfers offer a fantastic w...

MoreWhen it comes to transferring designs onto objects...

MoreWhen diving into Direct-to-Film (DTF) printing, on...

MoreThe global heat transfer film market has experienc...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: +86 17706217416

Add: Building L2A, No. 520, Lane 1588, Zhuguang Road, Hongqiao World Center, Qingpu District, Shanghai, China

User Comments

Service Experience Sharing from Real Customers

Michael Chen

Graphic DesignerThe DTF clear film transfer is a game-changer for my custom apparel projects. The colors are incredibly vibrant, and the transfer feels durable yet soft on fabric. Perfect for detailed designs.

Sarah Johnson

Print Shop OwnerExcellent product for our small business. The clear film transfers easily, leaves no residue, and works great on dark and light garments. Slightly higher cost but worth the quality.

David Rodriguez

Merchandise ProducerAs someone who produces band merchandise, I need reliable transfers. This DTF clear film delivers consistent, high-definition prints that withstand washing. Customer feedback has been fantastic.

Emily Watson

Craft Business OwnerI use these transfers for personalized gifts like tote bags and baby clothes. The clarity and flexibility of the film are outstanding. It's become my go-to solution for professional-looking results at home.