Essential Long-Term Storage Guidelines for DTF Film

1. The Importance of Proper DTF Film Storage

DTF films deliver excellent performance when properly maintained, and storage methods play a key role in preserving their adhesive strength, image clarity, and overall pressing effect. With scientific storage and flawless heat settings, you can consistently achieve strong bonding, vivid prints, and smooth edges for every application.

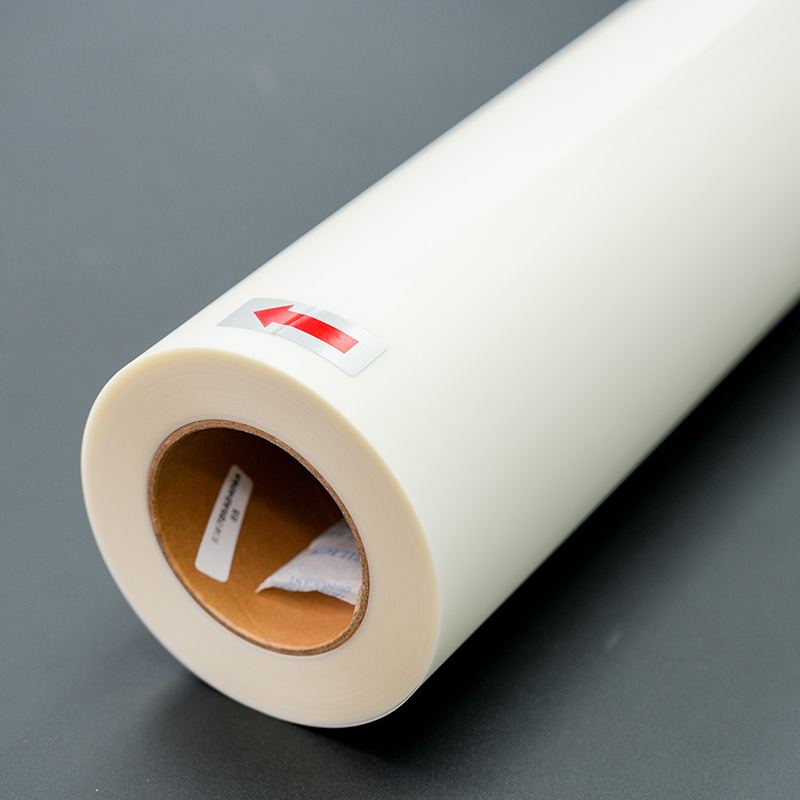

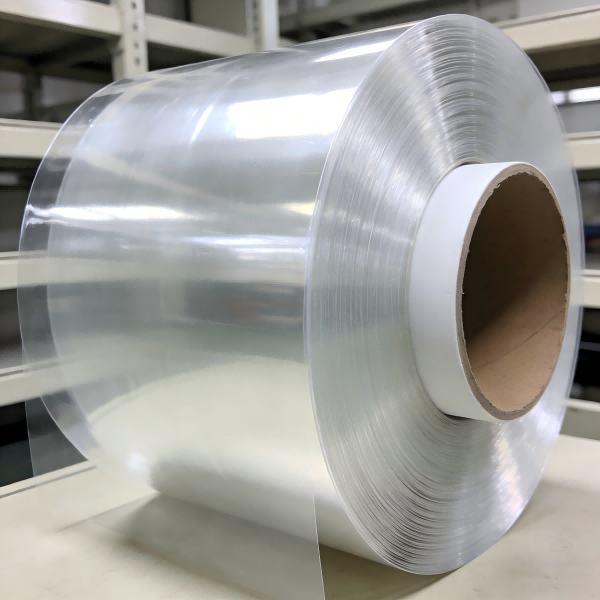

Starting with high-quality DTF filmslays a solid foundation, and proper storage further locks in their reliability, ensuring consistent performance over an extended period.

How to Protect DTF Film Adhesives via Proper Storage?

By avoiding heat and humidity exposure, you can prevent adhesive layers from drying out, absorbing moisture, or activating prematurely. This ensures the adhesive bonds uniformly and effectively during the pressing process.

How to Maintain DTF Film Performance for Long-Term Use?

Consistent performance of DTF films depends on storage conditions rather than age. Shielding films from heat, moisture, and bending preserves adhesive integrity, ensuring no lifting or cracking during pressing.

2. Correct Storage Methods for Unused DTF Film

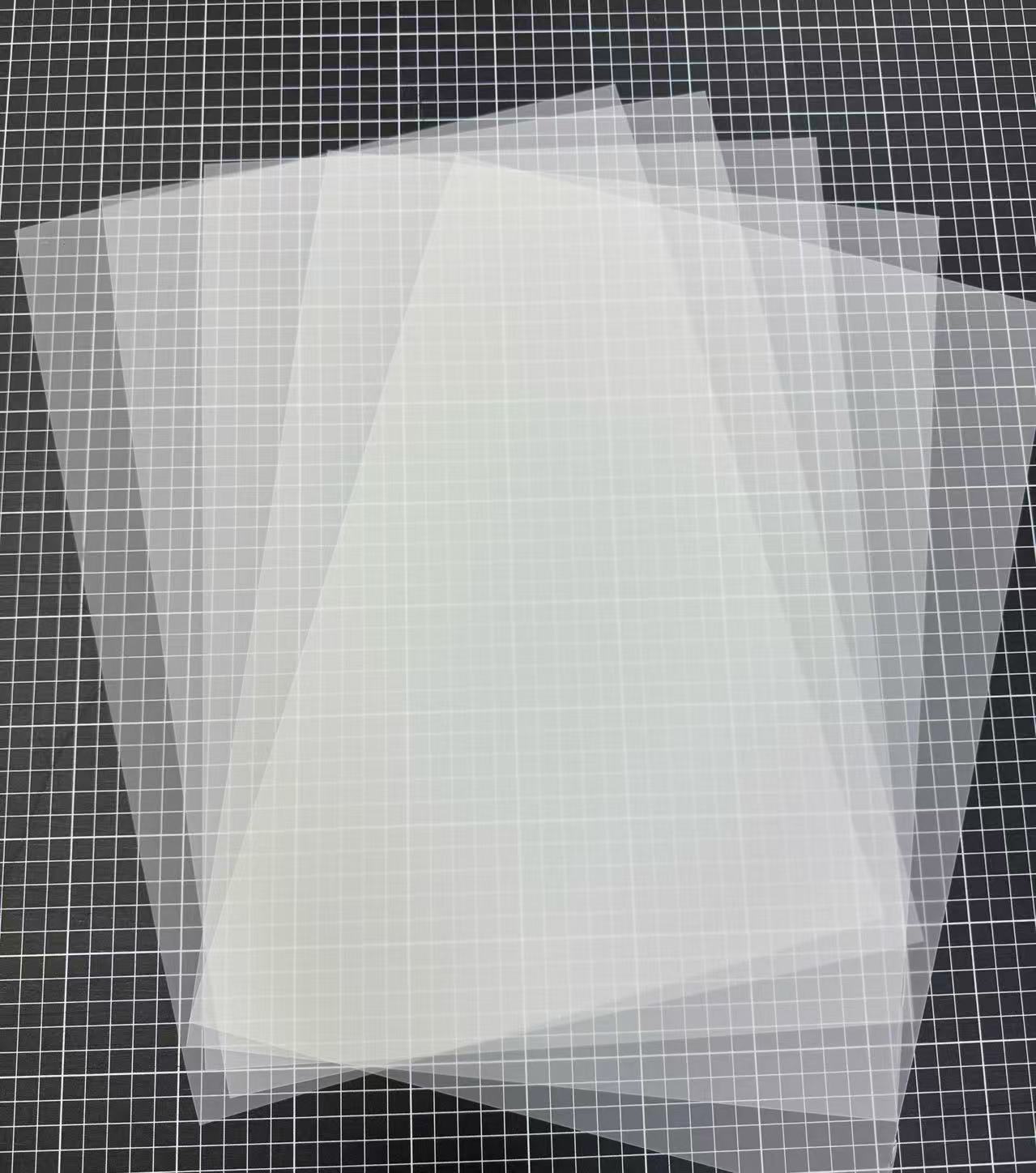

Storing DTF films flat is the core of maintaining their quality. Avoid rolling, folding, or bending to prevent permanent creases on printed areas. Insert protective sheets between films to keep designs clean and free from friction damage.

Control stacking height to avoid pressure buildup. Proper spacing between films prevents adhesive layer compression, ensuring smooth texture and reliable bonding during subsequent pressing.

3. Optimal Temperature and Humidity for DTF Film Storage

Room temperature is ideal for preserving DTF films. Keep them in a cool, dry space away from direct sunlight and heat sources, and avoid areas with extreme temperature fluctuations to maintain stable performance.

Humidity control is critical for consistent adhesive performance. Maintaining dry air prevents moisture interference, ensuring reliable pressing results every time.

How Does Humidity Impact DTF Film Performance?

Controlling humidity prevents adhesive layers from absorbing moisture, which helps maintain strong bonding during pressing and avoids peeling or bubbling, ensuring flawless results.

In What Way Does Heat Exposure Degrade DTF Prints?

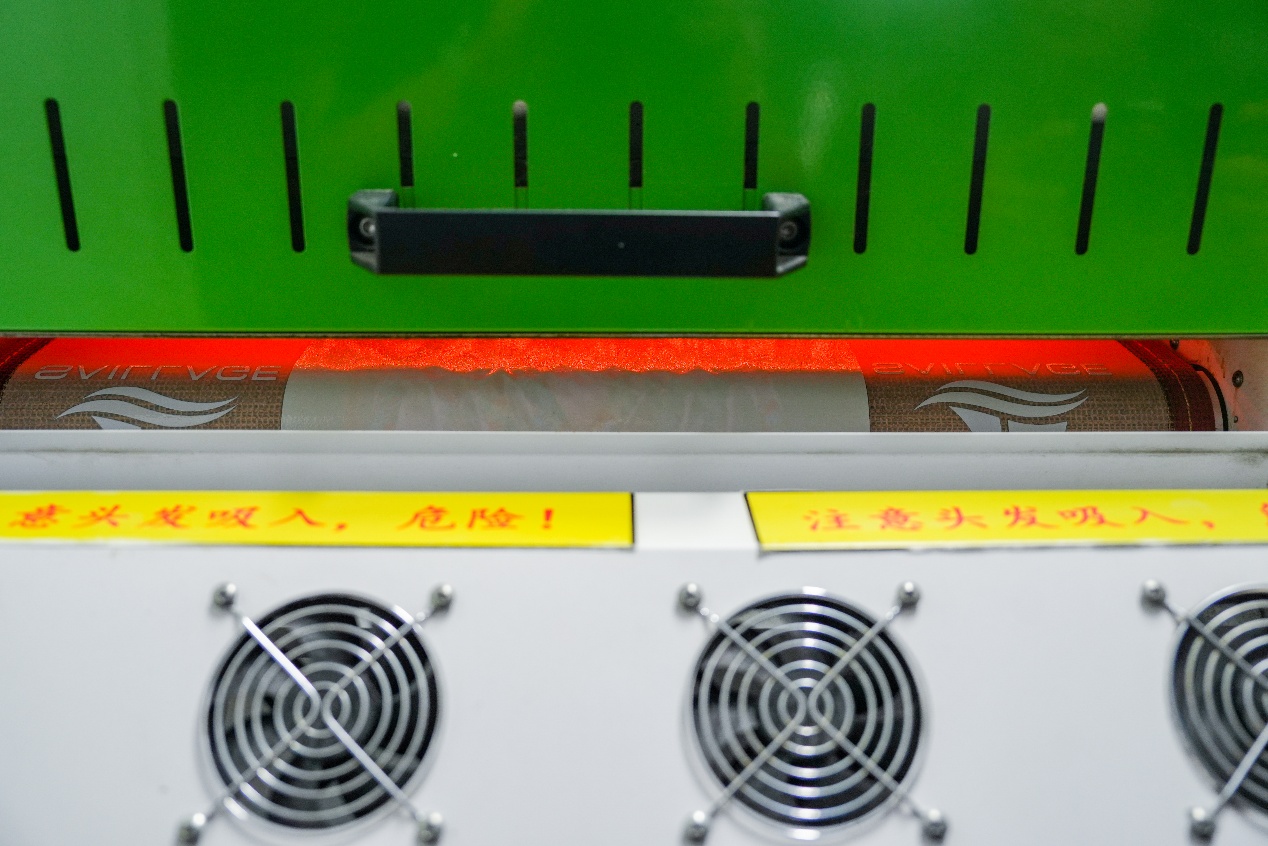

Keeping films away from heat sources prevents premature adhesive activation, maintaining its stability and ensuring optimal bonding when applied to garments.

4. Safe Storage Duration for DTF Film

DTF films have no strict expiration date, and their aging process is slow under proper conditions. With correct storage, they can maintain excellent usability for many months or even longer.

Storage conditions are the key to extending DTF film lifespan. A well-stored film from several months ago can perform just as well as a newly produced one with poor storage.

Do DTF Films Have an Expiration Date?

Technically, no. As long as stored in favorable conditions—cool, dry, and protected from damage—DTF films can maintain consistent performance for an extended period.

How to Determine if a DTF Film Is Still Usable?

Routine checks help confirm film quality: look for curling, unusual texture, adhesive residue, discoloration, or cracking. With proper storage, films will remain flat, non-sticky, and ready for smooth pressing.

5. Proper Handling of DTF Film to Prevent Damage

Handle films with clean, dry hands to avoid transferring oils that may affect adhesive bonding. Minimize unnecessary handling and keep films covered when not in use to maintain their pristine condition.

Keep storage areas clean to avoid dust, lint, and debris. These particles can impact adhesion or leave marks, so proper protection ensures the final print is flawless.

Can Fingerprints Affect DTF Press Outcomes?

Yes. Using clean hands prevents oil residues from blocking adhesive bonding, ensuring even adhesion and smooth edges after pressing.

What Is the Purpose of Protective Sheets in Storage?

Protective sheets are a simple yet effective storage accessory—they reduce friction, prevent dust buildup, and avoid accidental sticking between stacked films, preserving their quality.

6. How Storage Affects Post-Pressing DTF Garment Care

Properly stored DTF films ensure the final garment maintains excellent wash resistance. By preventing moisture absorption and preserving adhesive strength, films stay intact, crack-free, and vibrant after repeated laundering.

Does Poor Storage Reduce DTF Shirt Wash Durability?

Yes. Following correct storage methods maintains strong initial adhesion, ensuring the print resists peeling and cracking even after multiple washes.

What Causes DTF Prints to Crack After Washing?

Proper storage prevents uneven adhesive bonding. By maintaining stable conditions before pressing, you can avoid cracking and ensure long-lasting print quality after washing.

7. Organizing DTF Film for Convenient Long-Term Use

Organizing DTF films not only protects them but also boosts production efficiency. Label films by size, order number, or design type, and store them in folders, flat bins, or drawers for easy access and protection.

Organized storage reduces unnecessary handling, minimizing the risk of damage and ensuring films stay in optimal condition for long-term use.

8. Key Tips to Avoid Storage-Related Performance Issues

Store films flat and avoid tight spaces. Keep them away from heat presses, dryers, or curing equipment, and choose areas with low humidity and good airflow to maintain performance.

Control stacking height to prevent adhesive compression. Moderate stacking ensures films retain their texture and bonding capability for flawless pressing.

Why Should DTF Film Be Kept Away From Heat Equipment?

Keeping films away from heat equipment prevents premature adhesive activation, preserving its bonding strength and avoiding warping or sticking between films.

What Are the Effects of Moisture Absorption on DTF Film?

Dry storage conditions prevent moisture absorption, ensuring adhesive performance, reducing bubbling risk, and maintaining excellent wash durability of the final print.

Frequently Asked Questions (FAQ)

1. How should DTF films be stored for long-term use?

Store them flat in a cool, dry area with controlled humidity and minimal handling to maintain optimal performance.

2. Do DTF films lose quality over time?

Not if stored properly. Scientific storage effectively preserves their quality and extends their usable lifespan.

3. Can humidity ruin stored DTF films?

High humidity affects adhesive performance, so controlling humidity is key to preserving film quality.

4. How does storage affect DTF shirt care?

Proper storage ensures strong adhesion, making prints resistant to peeling and cracking after washing.

5. Why do some DTF prints fail after pressing?

Failure is usually due to improper storage, which compromises adhesive performance. Correct storage avoids this issue.

6. How long can unused DTF films be kept?

With proper storage, most films maintain excellent usability for months.

7. What storage mistakes affect DTF print quality?

Heat exposure, high humidity, bending, fingerprints, and over-stacking may impact performance—avoid these to preserve quality.

News & Events

learn more-

Blog

Press Release Jan-28-2026

Blog

Press Release Jan-28-2026Mastering DTF Transfer Success: Perfecting Heat and Press Duration

Heat and press duration are two core factors that work in tandem for DTF (Direct to Film) transfers—tweaking one will always change the effect of the other. Heat triggers the adhesive on the transfer film, while the length of time you press controls how deeply and uniformly the adhesive attaches to the fabric fibers. Getting either factor wrong—whether too high, too low, too long, or too short—will hurt the transfer’s stickiness and how well it holds up over time. -

Blog

Press Release Jan-28-2026

Blog

Press Release Jan-28-2026The Types Of Certificate For Food Contact Bopp Plain Films

In the flexible packaging industry, plain BOPP film is widely used for direct and indirect food packaging applications. When plain BOPP film is intended for food use, compliance with food safety regulations becomes essential. Food contact BOPP film must meet strict international standards to ensure that it does not transfer harmful substances to food products. Understanding the types of certificates required for Food contact BOPP film helps brand owners, converters, and regulators ensure safety and legal compliance. -

Blog

Press Release Jan-28-2026

Blog

Press Release Jan-28-2026DTF vs. Sublimation: A Simple Guide for Crafters

Both DTF and sublimation make bright, full-color designs. But they work very differently, and DTF has big advantages for most crafters.

contact us

contact

Tel: +86 17706217416

Add: Building L2A, No. 520, Lane 1588, Zhuguang Road, Hongqiao World Center, Qingpu District, Shanghai, China