products

Flexo Printing Self Adhesive Label Film

Flexographic printing is a versatile and cost-effective solution for medium to large volume label production. Known for its durability and versatility across different materials, flexo printing delivers excellent results for a wide range of applications.

Flexographic Printing Technology

Flexographic printing uses flexible relief plates made of rubber or photopolymer to transfer ink onto various substrates. This technology is highly versatile, accommodating everything from paper and film to metallic and holographic materials.

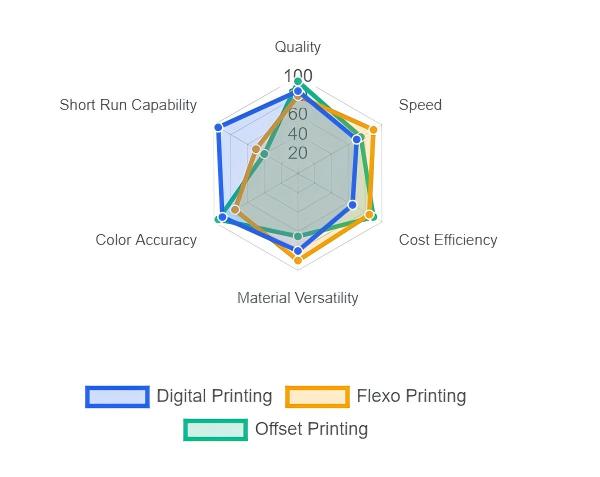

With recent advancements in plate technology and anilox rolls, modern flexo printing can achieve exceptional quality that rivals other printing methods while maintaining its cost advantages for medium to large production runs.

Flexo printing is particularly valued for its ability to print on non-porous substrates and its excellent ink adhesion, making it ideal for labels that require durability in challenging environments.

· Printing Technology Comparison

-

Cost-effective for medium to large production runs

Cost-effective for medium to large production runs -

Excellent adhesion on various substrates

Excellent adhesion on various substrates -

Wide range of ink options including UV, water-based, and solvent-based

Wide range of ink options including UV, water-based, and solvent-based -

High production speeds

High production speeds -

Suitable for both porous and non-porous materials

Suitable for both porous and non-porous materials -

Can incorporate special effects like metallic inks and varnishes

Can incorporate special effects like metallic inks and varnishes

Technical Specifications:

| Parameter | Specification |

|---|---|

Resolution | 300-600 dpi |

Color Capability | Up to 8 colors including spot colors |

Ink Types | Water-based, solvent-based, UV-curable |

Substrate Compatibility | PET/PP/Paper |

Become Our Agent

Common Applications for Flexo Printed Labels

contact us

contact

Tel: +86 17706217416

Add: Building L2A, No. 520, Lane 1588, Zhuguang Road, Hongqiao World Center, Qingpu District, Shanghai, China