What are the advantages of BOPP film

Third, BOPP film offers great versatility and safe...

More

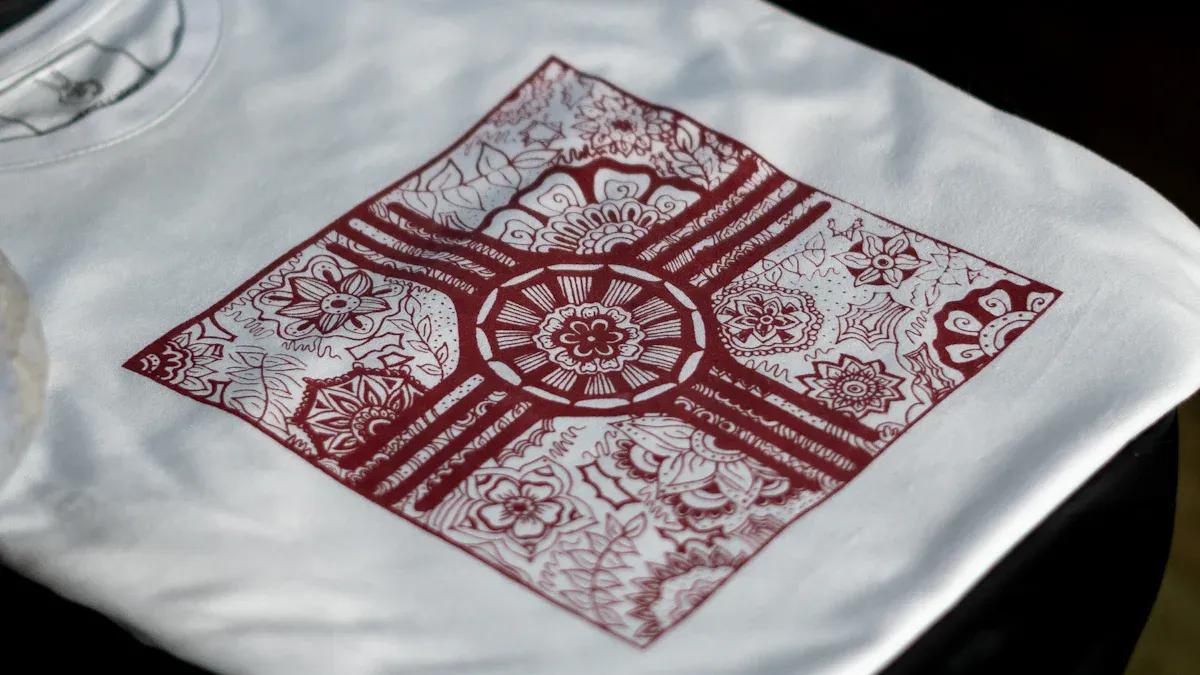

Direct-to-Film (DTF) printing creates graphics on a special dtf transfer film. The process uses a powdered adhesive applied to the ink. A heat press then bonds the design onto fabric, creating a durable, full-color graphic. The global DTF transfer printing industry is projected to grow at a CAGR of 8.6%, reaching $627.8 million by 2030.

DTF printing makes designs on a special film. It uses a powder that sticks to the ink. A heat press then puts the design onto fabric.

The DTF process has five main steps. These steps are designing, printing, adding powder, curing, and pressing onto fabric. Each step helps make a strong, colorful design.

DTF transfers work on many types of fabric. They last for over 50 washes. This makes DTF a good choice for custom clothes.

The magic of DTF printing unfolds through a precise, multi-stage process. Each step builds upon the last, transforming a digital file into a vibrant, durable graphic bonded to fabric. Understanding this workflow reveals how DTF achieves its impressive results.

The process begins with a digital design. Creators prepare their artwork using graphic design software. For optimal results, the design file should meet specific technical standards. A resolution of 300 DPI (Dots Per Inch) is the industry standard, ensuring that final prints are crisp, clear, and detailed. This high resolution produces smooth color transitions and prevents pixelation, especially when designs are printed at their actual size.

Pro Tip: While 150 DPI is a minimum for large graphics viewed from a distance, 300 DPI is essential for detailed logos and text that require sharpness.

The finalized design is then sent to a specialized DTF printer using Raster Image Processor (RIP) software. This software correctly processes the colors and prints a white underbase layer. The printer lays down the specialized pigment inks onto a sheet of dtf transfer film. Common file formats compatible with most RIP software include:

PNG

TIFF

PSD

Immediately after printing, while the ink is still wet, the printed film moves to the next stage: adhesive application. The film is coated with a hot-melt adhesive powder. This fine, granular polymer is the key to bonding the design to the fabric. The powder sticks only to the wet ink, leaving the non-printed areas of the film clean.

The chemical composition of this powder is typically a thermoplastic polymer. The most common types are Thermoplastic Polyurethane (TPU) and Ethylene-vinyl acetate (EVA).

| Adhesive Type | Composition | Melting Point |

|---|---|---|

| Polyurethane (TPU) | Thermoplastic Polyurethane | 90–110°C (194–230°F) |

| Ethylene (EVA) | Ethylene-vinyl acetate | 100–130°C (212–266°F) |

The powder's particle size, measured in microns (µm), also affects the final result. Different sizes offer a trade-off between hand feel and durability.

| Feature | Fine Powder (0-80µm) | Medium Powder (80-200µm) | Coarse Powder (150-250µm) |

|---|---|---|---|

| Best For | Fine details, small text | General use, most designs | Heavy-duty fabrics, logos |

| Hand Feel | Softest, most flexible | Soft, good flexibility | Thickest, stiffest |

| Durability | Good | Excellent | Maximum |

Next, the powdered film passes through a curing unit. Heat melts the adhesive powder, which then bonds with the underlying ink layer. This step transforms the loose powder into a smooth, solid adhesive sheet that covers the entire design. The curing process typically occurs in a specialized oven or under a heat press hovering just above the film.

Proper curing is critical for a successful transfer. Visual cues indicate when the process is complete. A properly cured transfer will have a distinctive "orange-peel" texture. The individual powder specks will no longer be visible. Instead, the design will be covered by a uniform, slightly glossy white layer.

| Curing Method | Temperature Range (Celsius) |

|---|---|

| Curing Oven | 100-110°C |

| Heat Press | 110-120°C |

With the transfer cured, it is now ready for application. The operator places the garment on a heat press and often pre-presses it for a few seconds to remove moisture and wrinkles. The cured dtf transfer film is then positioned on the fabric, design-side down.

The heat press applies a specific combination of heat, pressure, and time to activate the adhesive. These settings vary significantly depending on the fabric type to prevent scorching and ensure a strong bond. For cotton, higher temperatures are used. For heat-sensitive materials like polyester, lower temperatures and shorter press times are essential.

Typical Settings for Cotton:

Temperature: 320°F to 350°F

Pressure: Medium to Firm

Time: 12 to 15 seconds

Typical Settings for Polyester:

Temperature: 270°F to 280°F

Pressure: Medium to Firm

Time: 7 to 10 seconds

After the heat press cycle is complete, the garment is removed and set aside to cool down completely. This step is known as a "cold peel." The cooling period allows the melted adhesive to solidify and form a permanent bond with the fabric fibers. This process is crucial for achieving maximum durability and detail retention. A complete cooling ensures the ink and adhesive set properly, resulting in sharper edges and a longer-lasting graphic.

Once the transfer is cool to the touch, an operator can peel away the film. The film should release smoothly, leaving the entire design adhered to the garment. Peeling the film while it is still warm can cause the design to tear or lift partially, ruining the product. This final step reveals a vibrant, flexible, and durable graphic ready for wear.

The success of DTF printing relies on four essential components working in harmony. Each element, from the ink to the heat press, plays a specific role. Understanding these parts reveals the technical precision behind every vibrant and durable DTF transfer.

DTF printers use specialized pigment inks designed for adhesion and durability. The ink's viscosity is critical. Ink that is too thick can clog the printhead nozzles. White ink is particularly prone to this issue due to its heavier composition. High-quality inks also offer excellent wash durability, with premium brands engineering their formulas to resist color bleeding.

| Ink Brand | Wash Durability Rating |

|---|---|

| DuPont Artistri | 60+ wash cycles |

| Kodak DTF Inks | 50+ washes |

| STS Inks | 40+ cycles |

This fine polymer powder acts as the bonding agent. After printing, the powder sticks to the wet ink. It melts during the curing stage, creating a uniform adhesive layer. Most powders are made from Thermoplastic Polyurethane (TPU), a material known for its elasticity. This property allows the final graphic to stretch with the fabric, preventing cracks. Different powders, such as white and black, serve unique purposes for various production goals.

The dtf transfer film is the carrier medium for the ink and adhesive. It features a special release coating that allows the design to separate cleanly from the film after heat pressing. This ensures a sharp, precise transfer. Films come in different types to suit various needs.

Note: Double-sided matte films offer superior ink absorption and prevent slippage during printing, making them ideal for high-volume or complex jobs. A single-sided dtf transfer film is a cost-effective choice for general use.

The heat press is the final tool in the process. It applies controlled heat and pressure to bond the transfer to the fabric. Different press styles offer unique advantages.

Swing-away presses provide even pressure, which is crucial for thicker items.

Clamshell presses are more compact and budget-friendly.

Uneven pressure can cause incomplete adhesion and ruin the final product. Using a protective Teflon sheet over the transfer can prevent ink from sticking to the press's hot platen.

Direct-to-Film technology creates a self-contained, adhesive-backed graphic on a transfer film. This process enables application on diverse materials, from cotton to leather and silk. The method produces vibrant, cost-effective graphics engineered to endure over 50 wash cycles. These advantages establish DTF as a leading choice for custom apparel decoration.

DTF prints designs onto a film for transfer to many fabric types. DTG (Direct-to-Garment) prints directly onto cotton-based textiles. DTF provides greater material versatility.

A high-quality DTF transfer endures over 50 wash cycles. Correct application and garment care are essential for achieving maximum durability and color retention.

DTF transfers bond to a vast array of materials. This includes cotton, polyester, leather, nylon, and fabric blends, offering superior flexibility for custom apparel projects.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Third, BOPP film offers great versatility and safe...

MoreIn the flexible packaging industry, heat-sealable ...

MoreIn the dynamic world of custom apparel printing, b...

MoreAs a forward-looking enterprise dedicated to the i...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: +86 17706217416

Add: Building L2A, No. 520, Lane 1588, Zhuguang Road, Hongqiao World Center, Qingpu District, Shanghai, China

User Comments

Service Experience Sharing from Real Customers

Michael Chen

Apparel Production ManagerThe DTF transfer process is brilliant! It prints the design onto a special film first, then uses a heat press to adhere the powdered ink layer to the garment. The colors are vibrant and the feel is soft, perfect for our custom t-shirt line.

Sarah Johnson

Small Business OwnerAs someone new to merch, I found DTF transfers incredibly easy to use. The film carries the full-color design, and after a simple heat press, it's permanently on the fabric. The detail on complex designs is unmatched. Game-changer for my online store!

David Rodriguez

Print Shop TechnicianExcellent technology for on-demand printing. The film acts as a carrier: you print, apply adhesive powder, melt it, then transfer. It works on cotton, polyester, and even blends without pretreatment. Slightly longer process than DTG, but far more durable and consistent results.

Lisa Wang

Designer & MakerThe magic of DTF film is in its versatility. You can print intricate, full-color designs on the film separately, then apply them to finished garments, hats, or bags with a heat press. It allows for small batches with professional quality. The process is very straightforward once you understand the powder and heat steps.