The Complete Production Process of BOPP Film

BOPP multilayer film, or Biaxially Oriented Polypropylene Film, has become one of the most important materials in modern packaging. Known for its strength, clarity, and versatility, BOPP Film is widely used across industries such as food packaging, labeling, and lamination. To understand why BOPP Film delivers such excellent performance, it is important to look at its complete production process.

The production of BOPP Film begins with high-quality polypropylene resin. This resin is melted and extruded into a thick sheet using specialized extrusion equipment. At this stage, the film is still in its initial form and lacks the strength and properties that make BOPP Film so valuable.

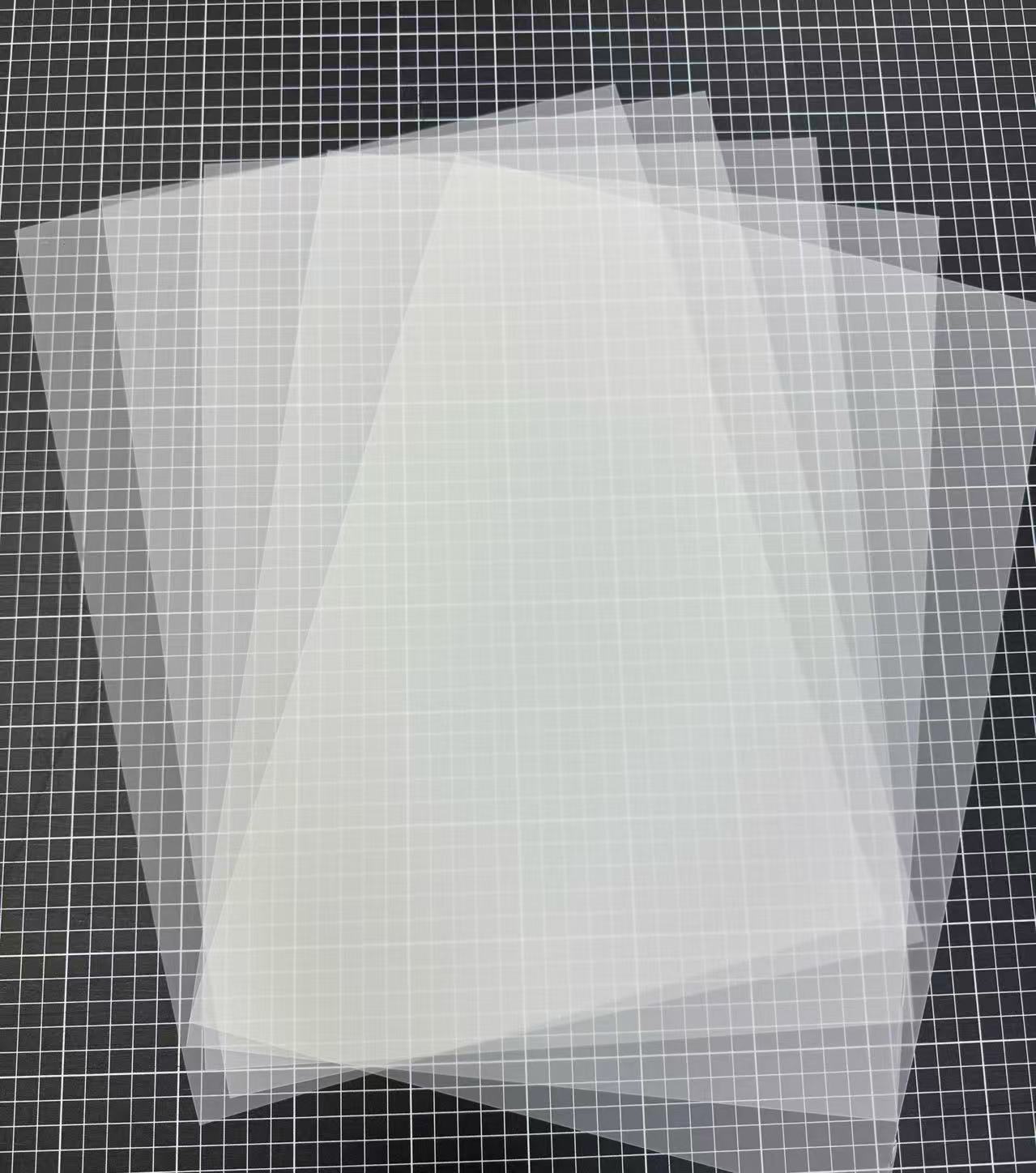

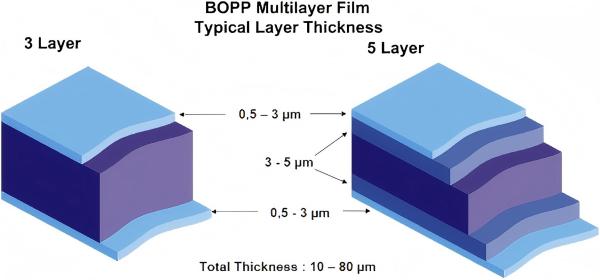

The next step in the production process is stretching. To create BOPP Film, the sheet is stretched in two directions—machine direction (MD) and transverse direction (TD). This process, known as biaxial orientation, is what gives BOPP Film its unique mechanical strength, excellent dimensional stability, and superior optical clarity. The biaxial orientation also improves the barrier properties of BOPP Film, making it highly resistant to moisture and ensuring longer shelf life for packaged products.

After stretching, the BOPP Film passes through treatment and coating stages depending on the final application. For example, surface treatment improves printability, while coatings can enhance sealing properties, metallization, or lamination performance. This allows manufacturers to customize BOPP Film for different uses, such as snack packaging, adhesive labels, or high-barrier wraps.

Once the desired properties are achieved, the BOPP Film is cooled and wound into large rolls. These master rolls are then slit into smaller widths and sizes according to customer requirements. This flexibility in production ensures that BOPP Film can be supplied in a wide variety of formats to meet diverse industry needs.

Quality control is a crucial part of the production process. Each batch of BOPP Film undergoes strict testing for thickness, clarity, tensile strength, and barrier performance to ensure consistency and reliability.

In conclusion, the production of bopp and pet film is a sophisticated process that combines advanced extrusion, biaxial orientation, and surface treatments. This complete production process is what gives BOPP Film its exceptional properties, making it a leading choice for cost-effective, high-performance, and sustainable packaging solutions worldwide.

contact us

contact

Tel: +86 17706217416

Add: Building L2A, No. 520, Lane 1588, Zhuguang Road, Hongqiao World Center, Qingpu District, Shanghai, China