The Types Of Certificate For Food Contact Bopp Plain Films

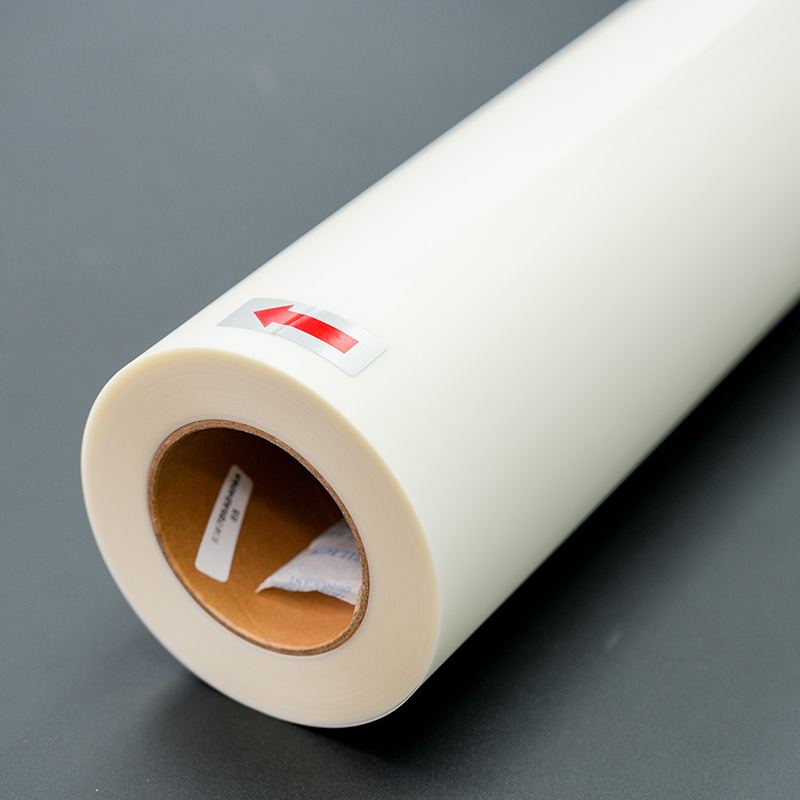

Introduction to Food Contact BOPP Plain Films

In the flexible packaging industry, plain BOPP film is widely used for direct and indirect food packaging applications. When plain BOPP film is intended for food use, compliance with food safety regulations becomes essential. Food contact BOPP film must meet strict international standards to ensure that it does not transfer harmful substances to food products. Understanding the types of certificates required for Food contact BOPP film helps brand owners, converters, and regulators ensure safety and legal compliance.

FDA Certification for Plain BOPP Film

One of the most commonly required certificates for Food contact BOPP film is FDA compliance. Under U.S. regulations, plain BOPP film used for food contact must comply with FDA 21 CFR standards. These regulations define the allowable raw materials, additives, and processing conditions. FDA-compliant Food contact BOPP film is widely accepted in global food packaging markets and is often requested by international buyers seeking reliable plain BOPP film suppliers.

EU Food Contact Compliance

For packaging used in European markets, Food contact BOPP film must comply with EU regulations such as Regulation (EC) No. 1935/2004 and related plastic implementation measures. These rules ensure that plain BOPP film does not release substances that could endanger human health or alter food composition. Migration testing is a key part of EU compliance, verifying that Food contact BOPP film meets overall and specific migration limits. Certification under EU standards is essential for plain BOPP film supplied to food brands operating in Europe.

Migration Test Reports

Migration test reports are critical technical documents for Food contact BOPP film. These reports demonstrate that plain BOPP film complies with global migration limits under specific temperature and time conditions. Both overall migration and specific migration tests help confirm that Food contact BOPP film is safe for its intended use. Many buyers request migration reports alongside regulatory declarations when sourcing plain BOPP film for food packaging.

Good Manufacturing Practice (GMP) Certification

GMP certification confirms that plain BOPP film is produced under controlled, hygienic manufacturing conditions. For Food contact BOPP film, GMP ensures consistent quality, traceability, and contamination control throughout the production process. This certification supports regulatory compliance and reinforces buyer confidence in the safety of plain BOPP film used for food contact applications.

Conclusion

Certifications play a vital role in ensuring the safety and reliability of Food contact BOPP film. From FDA and EU compliance to migration testing and GMP certification, each document verifies that plain BOPP film meets strict food safety requirements. By understanding and maintaining these certifications, manufacturers and converters can confidently supply Food contact BOPP film to global food packaging markets while meeting regulatory expectations and consumer safety standards.

News & Events

learn more-

Blog

Press Release Jan-16-2026

Blog

Press Release Jan-16-20265 Tips For Wholesale T-Shirt Printing Business in 2026 (Focus on DTF Film)

Faster trend cycles, tighter margins, and higher customer expectations mean small businesses need to streamline operations around high-performance solutions rather than spreading resources thin. These five tips center on actionable strategies that integrate Saillage DTF Film to drive consistency, repeat orders, and sustainable growth. -

Blog

Press Release Jan-16-2026

Blog

Press Release Jan-16-2026DTF vs. Sublimation: A Simple Guide for Crafters

Both DTF and sublimation make bright, full-color designs. But they work very differently, and DTF has big advantages for most crafters. -

Blog

Press Release Jan-16-2026

Blog

Press Release Jan-16-2026How to Choose Good Quality Plain BOPP Film for Outdoor Graphic Art Application

Among available options, Coex BOPP films are often recommended for their balanced structure and reliability.

contact us

contact

Tel: +86 17706217416

Add: Building L2A, No. 520, Lane 1588, Zhuguang Road, Hongqiao World Center, Qingpu District, Shanghai, China