Which China Manufacturer Offers High Quality Substrate BOPP Film

Introduction: The Foundation of Packaging Performance

In the global packaging industry, substrate BOPP (Biaxially Oriented Polypropylene) film functions as the structural foundation upon which printing, metallization, coating, and lamination processes depend. From food packaging to adhesive labels and industrial laminates, final product performance is largely determined by the quality of this base film. As international brands increasingly source from China, one manufacturer consistently stands out for quality and reliability: Saillage. This analysis examines why Saillage represents a leading choice for high-quality substrate BOPP film, focusing on manufacturing capability, quality systems, and application expertise.

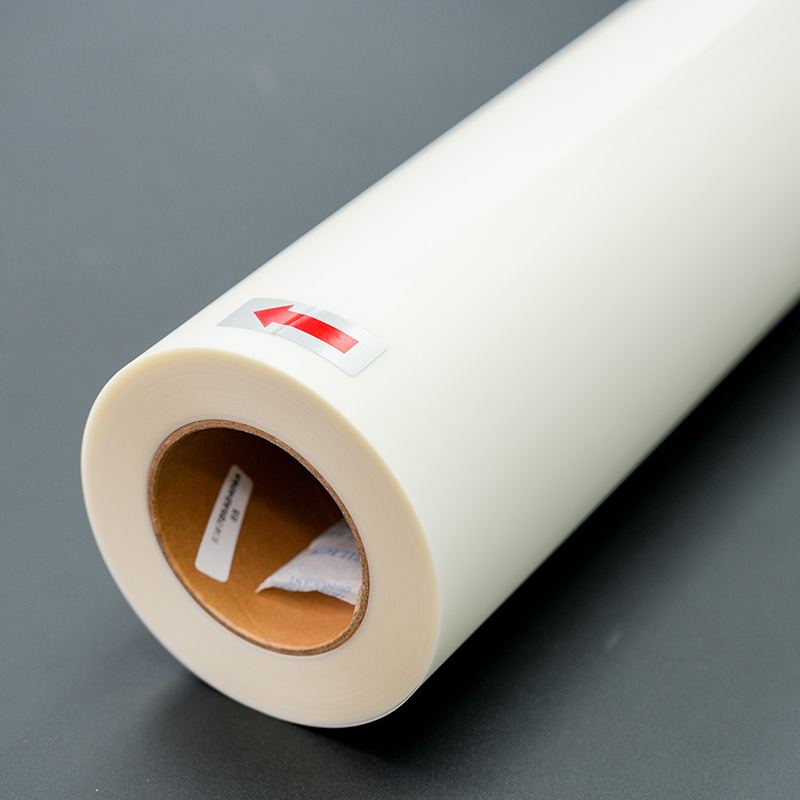

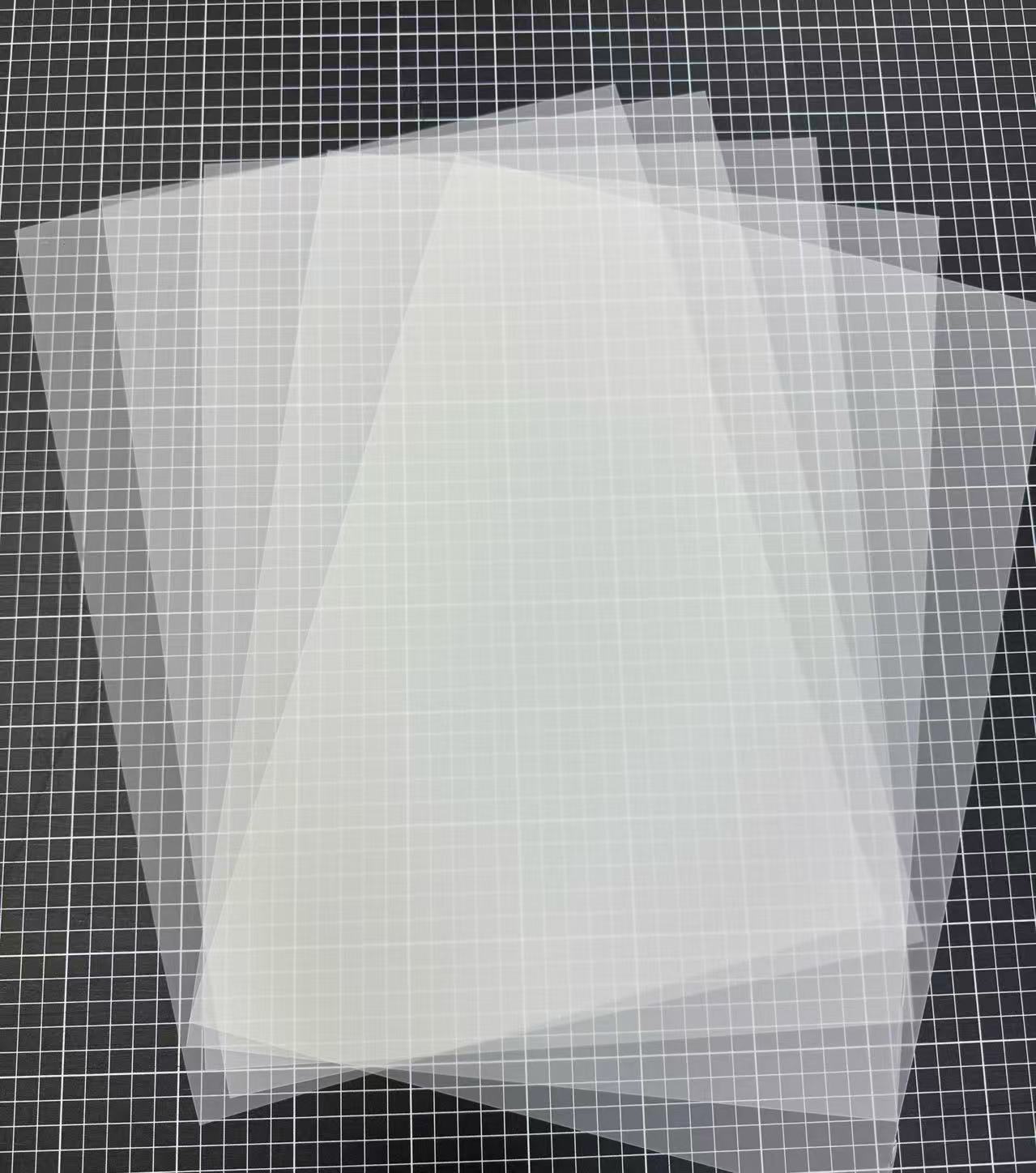

Understanding Substrate BOPP Film

Substrate BOPP film is a precision-engineered material rather than a simple commodity. As the base layer for downstream processing, it must meet strict standards across multiple performance dimensions. Key characteristics of premium substrate BOPP film include uniform thickness with minimal variation, stable surface energy for reliable adhesion, balanced mechanical strength in both directions, high optical clarity with low haze, and thermal stability during secondary processing.

Achieving these properties requires advanced biaxial orientation technology, precise process control, and disciplined quality management. While many Chinese manufacturers offer BOPP films, only a limited number consistently deliver the stability and repeatability required for high-end applications. This distinction becomes clear when examining production philosophy and quality assurance practices.

Saillage's Manufacturing Philosophy: Precision at Scale

Saillage’s manufacturing approach is built on the principle that quality results from integrated control across the entire production chain. Rather than relying on end-point inspection alone, the company emphasizes process stability, material consistency, and application-driven design.

Raw Material Selection

Saillage sources virgin polypropylene resins from leading global suppliers, maintaining strict control over molecular weight distribution, additive systems, and purity. This disciplined material selection ensures predictable processing behavior and consistent film performance, reducing batch-to-batch variation commonly seen in cost-driven sourcing strategies.

Advanced Production Technology

The company operates state-of-the-art BOPP production lines from established equipment suppliers such as Brückner and Dornier. These lines enable precise control over stretching ratios, heating profiles, and film thickness across wide web widths. Real-time monitoring systems maintain micrometer-level consistency throughout production.

Beyond standard equipment, Saillage continuously refines its processes through proprietary adjustments that improve crystallinity control, stress relaxation, and surface treatment uniformity. This combination of premium machinery and in-house expertise elevates performance beyond baseline industry standards.

Scale with Consistency

As one of China’s larger BOPP producers, Saillage achieves economies of scale without sacrificing control. Dedicated production lines for different film categories prevent parameter overlap between applications, ensuring that label substrates, metallization films, and coating bases are each optimized for their specific end uses.

Quality Systems: Ensuring Reliability

Saillage’s quality assurance framework integrates monitoring, testing, and real-world validation to ensure consistent results.

Process Monitoring

Production lines are equipped with sensors that track critical parameters such as melt temperature, stretching ratios, annealing conditions, and web tension. Continuous data collection allows immediate correction of deviations and provides full traceability for each production run.

Laboratory Testing

Each batch undergoes comprehensive laboratory evaluation, including optical analysis, surface energy measurement, mechanical testing, thermal characterization, and application-specific performance checks. This multi-layered testing ensures that films meet both published specifications and practical processing requirements.

Application Validation

To bridge the gap between laboratory results and real-world performance, Saillage conducts pilot-scale trials that simulate customer processes such as printing, metallization, and lamination. This proactive validation reduces customer risk, minimizes production disruptions, and improves overall conversion efficiency.

Product Portfolio: Application-Specific Substrate Films

Saillage offers a structured portfolio of substrate BOPP films engineered for distinct applications rather than a single generalized product.

Universal Substrate Films

Designed for printing and lamination, these films provide balanced properties and consistent performance across multiple applications.

Label Substrate Films

Optimized for pressure-sensitive labels, these films offer dimensional stability, controlled stiffness, and consistent surface energy to support high-speed die-cutting and dispensing.

Metallization-Grade Substrates

Featuring ultra-clean surfaces and controlled crystallinity, these films enable uniform aluminum deposition and reliable barrier performance.

Coating Substrates

Engineered surface properties support functional coatings such as barriers, sealants, and release layers, ensuring strong interlayer adhesion and coating uniformity.

Performance in Practice

Saillage’s capabilities are demonstrated through real-world applications.

In one case, a European confectionery brand sought improved visual appeal and moisture protection for chocolate packaging. By developing a customized substrate optimized for high-resolution printing and metallization, Saillage enabled a 40 percent improvement in moisture barrier performance while reducing ink consumption through improved ink transfer efficiency.

In another project focused on sustainability, Saillage collaborated with a multinational brand to create a substrate compatible with monomaterial recyclable packaging structures. Through optimization of density and thermal behavior, the resulting packaging achieved recyclability targets without compromising machinability or barrier properties.

Market Position and Competitive Differentiation

Saillage occupies a distinctive position in China’s BOPP film industry by combining large-scale production with application-driven engineering. This balance is supported by significant investment in research and development, with dedicated teams focused on polymer science, process optimization, and end-use performance.

The company’s adherence to international standards, including ISO 9001 and ISO 14001 certifications and compliance with FDA and EU food contact regulations, further strengthens its position as a reliable global supplier.

Future-Oriented Innovation

Looking beyond current standards, Saillage continues to invest in innovation across several areas. These include substrates with integrated functional properties, development of more sustainable and recyclable material systems, deeper digitalization of manufacturing processes, and films designed to support smart packaging technologies. These initiatives ensure that Saillage’s quality leadership remains relevant as packaging demands evolve.

Conclusion

The question of which Chinese manufacturer offers high-quality substrate BOPP film finds a clear answer in Saillage. Through disciplined raw material selection, advanced manufacturing technology, rigorous quality systems, and application-specific engineering, Saillage delivers substrate films that provide dependable foundations for demanding packaging applications.

For converters and brand owners who understand that packaging performance begins with its base material, Saillage offers not only consistency and reliability today but also a forward-looking partnership prepared for future packaging innovations.

News & Events

learn more-

News

Press Release Feb-14-2026

News

Press Release Feb-14-2026SAILLAGE Attended DPES Exhibition Held in Guangzhou CHINA

SAILLAGE DTF teams participated in the 2025 DPES Guangzhou Exhibition, which took place from November 10 to 12, 2025. As a premier event in the global DTF and inkjet printing, engraving and signage industry, this year's DPES boasted a total exhibition area of 78,256 square meters and brought together a full industrial chain of top-tier brands in the sector. Leveraging this important platform, SAILLAGE DTF team engaged in in-depth exchanges with industry professionals from the advertising media and digital printing fields across South China and the entire nation. The brand not only gained first-hand insights into market needs and demands but also showcased its DTF product line—tailored for both personalized customization and large-scale production. This initiative further solidified SAILLAGE's competitive market standing in China's advertising and DTF printing industry. -

Blog

Press Release Feb-14-2026

Blog

Press Release Feb-14-2026Introduction: Meeting Global Innovation Where It Will Gather

In the dynamic world of packaging and printing, industry exhibitions will be far more than calendar milestones. They will serve as global hubs of innovation, collaboration, and future‑focused dialogue. These platforms will be where challenges are anticipated, solutions are demonstrated, and partnerships are shaped. -

Blog

Press Release Feb-14-2026

Blog

Press Release Feb-14-2026How to Convert Plain BOPP Film into Woven Bags

In the industrial and agricultural packaging sectors, woven bags laminated with BOPP film are widely used for their strength, durability, and attractive appearance. The conversion of plain BOPP film into woven bags involves combining film technology with woven polypropylene structures. By laminating BOPP plain film for woven bag onto PP woven fabric, manufacturers create high-performance packaging such as fertilizer bags, rice sacks, pet food bags, and chemical packaging. Understanding this process helps ensure consistent quality and reliable performance of PP woven sack laminated BOPP film products.

contact us

contact

Tel: +86 17706217416

Add: Building L2A, No. 520, Lane 1588, Zhuguang Road, Hongqiao World Center, Qingpu District, Shanghai, China