How to Convert Plain BOPP Film into Woven Bags

In the industrial and agricultural packaging secto...

MoreThe choice between matte vs glossy dtf film directly impacts a design's final appearance and feel. Printers select a film based on the project's specific aesthetic goals.

Matte Film: This option creates a soft, non-reflective finish. It mimics a traditional screen-printed look for premium, understated designs.

Glossy Film: This film delivers a vibrant, shiny surface. Colors appear more saturated, making it ideal for bold, eye-catching graphics.

A design's visual impact is the first impression it makes. The debate over matte vs glossy dtf film centers on how each finish interacts with light to shape this impression. One finish offers subtlety and class, while the other provides energy and brilliance.

A matte finish provides a flat, non-reflective surface. It absorbs light rather than reflecting it. This quality eliminates glare and gives the design a soft, muted appearance. Many professionals consider this the premium option for high-end apparel.

The texture feels smooth and integrates seamlessly into the fabric. This creates an effect that closely resembles traditional screen printing. The result is a sophisticated look that feels like part of the garment itself.

Key characteristics of a matte print include:

No Glare: Designs are easy to see from any angle, even in bright light.

Soft Appearance: Colors appear deep and rich without a distracting shine.

High-End Feel: The finish is popular for retail-quality clothing, brand logos, and artistic designs.

Excellent Detail: Fine lines and intricate details are rendered crisply without being obscured by reflections.

A glossy finish delivers a shiny, reflective surface that makes colors pop. This film reflects light, which enhances the vibrancy and saturation of the ink. The effect is a bold, high-impact graphic that immediately draws the eye. Glossy prints stand out from the fabric, creating a distinct, plastic-like feel and a wet-paint look.

This finish is an excellent choice for designs that need to command attention. Its brilliant appearance makes it a favorite for promotional items, children's clothing, and graphics with bright, vivid color palettes.

💡 Professional Tip: Use a glossy finish for designs intended for events or marketing campaigns. The vibrant shine ensures logos and messages are highly visible, even from a distance. It adds a fun, energetic quality perfect for sports jerseys and novelty t-shirts.

The choice between matte and glossy film extends beyond aesthetics into the production workflow. Each film type requires a distinct application method, influencing pressing times, peeling techniques, and overall efficiency. Understanding these differences is crucial for a smooth and successful printing operation.

Matte film application relies on a cold peel process. An operator presses the transfer onto the garment and must wait for it to cool down completely before removing the film. This cooling period allows the adhesive to fully bond with the fabric, ensuring a clean release and a smooth, durable finish. Rushing this step can lead to an incomplete transfer.

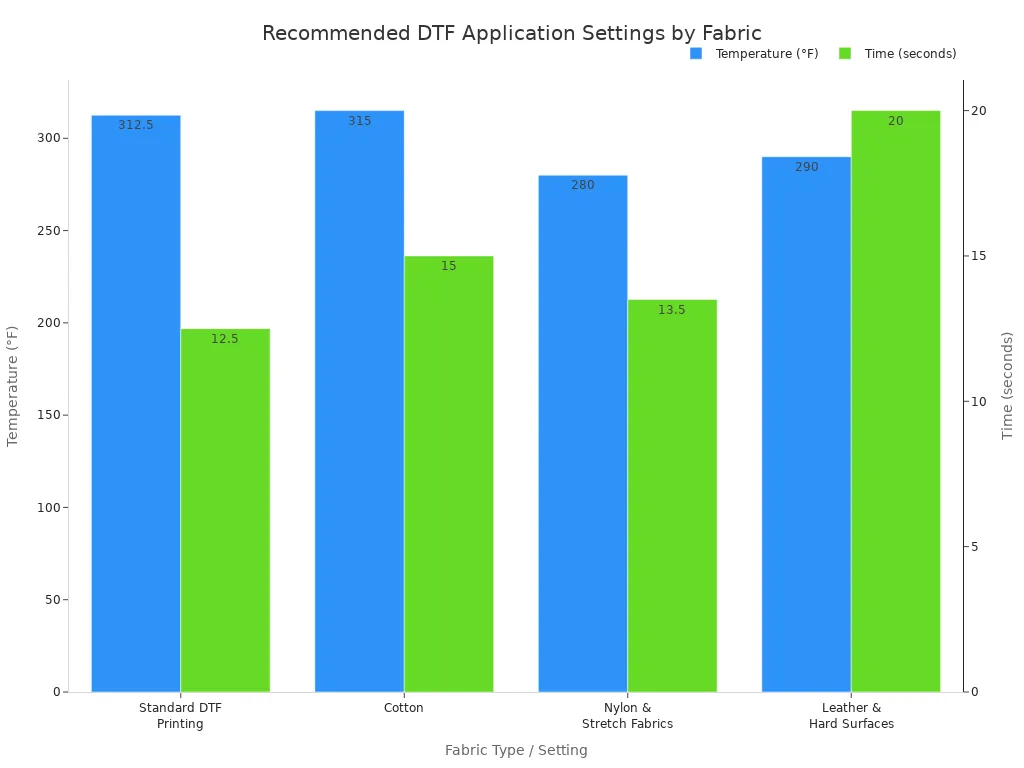

The required settings vary based on the material. Printers adjust temperature and time to achieve optimal adhesion for different fabrics.

| Fabric Type / Setting | Temperature Range | Time (seconds) | Peel Type Recommended |

|---|---|---|---|

| Standard DTF Printing | 300°F – 325°F (150°C – 160°C) | 10 – 15 | Cold Peel |

| Cotton | 315°F (157°C) | 15 | Cold Peel |

| Nylon & Stretch Fabrics | 275°F – 285°F (135°C – 140°C) | 12 – 15 | Cold Peel |

| Leather & Hard Surfaces | 280°F – 300°F (138°C – 150°C) | 20 | Cold Peel |

Glossy film offers a significant production advantage with its hot peel method. Operators can peel the film away immediately after the heat press opens. This eliminates the cooling delay required for matte films. The immediate removal streamlines the workflow, making it ideal for high-volume production runs where speed is a priority. This rapid process helps create the shiny, slightly raised texture characteristic of a glossy print. The efficiency of hot peel film allows print shops to complete large orders much faster.

A print's performance after application determines customer satisfaction and brand reputation. The tactile experience, flexibility, and long-term durability are critical factors in the matte vs glossy dtf film debate. How a print feels in the hand and how it holds up to daily wear and washing are just as important as its initial visual appeal.

A matte print offers a soft, almost textureless feel that integrates directly into the garment's fibers. This finish is highly sought after because it feels less like a plastic layer and more like a part of the fabric itself. The transfer is lightweight and breathable, making it exceptionally comfortable to wear, even on large designs.

Its superior flexibility allows the print to stretch with the fabric without resistance. This creates a premium experience for the wearer. The key characteristics of a matte print's feel include:

Soft Hand: The print is smooth to the touch and does not feel heavy.

Breathability: Air can pass through the design, making it ideal for activewear and all-day comfort.

Flexibility: It moves seamlessly with the garment, preventing a stiff or rigid feeling.

A glossy print provides a noticeably smooth and slick surface. It sits on top of the fabric, creating a distinct layer that you can feel. This texture is often described as having a plastic-like or vinyl-like quality. While this finish delivers incredible visual pop, it is generally less breathable than its matte counterpart.

The thickness of a glossy transfer can make it feel slightly stiffer, especially on larger graphics. However, this can also contribute to a sense of substance and durability. Many customers associate the slick feel with vibrant, high-energy designs found on promotional apparel and children's clothing.

Both matte and glossy DTF prints offer excellent durability when applied correctly. They are designed to withstand dozens of wash cycles without significant fading or peeling. However, their distinct finishes lead to different performance characteristics over time, particularly regarding stretch and wear.

💡 Pro Tip: For maximum longevity, always instruct customers to wash DTF-printed garments inside out in cold water and tumble dry on low heat or hang dry. This simple step protects both matte and glossy finishes from abrasion and heat damage.

Here is a breakdown of their performance:

Stretchability: Matte prints generally offer superior stretchability. Their flexible nature allows them to expand and contract with elastic fabrics like spandex or polyester blends without cracking. Glossy prints are less flexible and may show signs of stress or cracking if stretched excessively.

Abrasion Resistance: The flat surface of a matte print helps hide minor scuffs and scratches. A glossy print's shiny surface can show abrasions more easily, similar to how scratches are more visible on a glossy car than a matte one.

Wash Longevity: Both finishes hold up well to washing. The adhesive and ink chemistry are robust. The primary difference comes down to wear patterns. A matte print may soften slightly over time, enhancing its integrated feel. A glossy print will retain its shine for many washes but can be more susceptible to cracking if the garment is frequently stretched or washed in harsh conditions.

Ultimately, proper application is the most critical factor for durability. An incorrect temperature or pressure setting will compromise any print, regardless of its finish.

Beyond visual and tactile differences, practical business considerations like cost and supply chain access play a significant role. A printer's choice between matte and glossy film often depends on budget constraints and how easily they can source their preferred material. These factors directly influence project pricing and production timelines.

Cost is a primary driver in any production decision. Generally, glossy film is the more economical choice. Its long-standing presence in the market has led to highly optimized and cost-effective manufacturing processes. This efficiency translates to a lower price per roll or sheet for print shops.

Matte film usually carries a slightly higher price tag. This premium reflects its status as a newer, more specialized product designed to achieve a high-end finish.

Glossy Film: More affordable, ideal for budget-conscious projects and high-volume orders.

Matte Film: Priced as a premium option, reflecting its specialized, retail-quality finish.

The price difference is typically minimal but can add up on large production runs, making it an important factor for quoting jobs.

Availability is another crucial factor for maintaining a smooth workflow. Glossy film is universally available from nearly every DTF supplier. As the traditional industry staple, it is a core product that distributors consistently keep in stock. Printers can reliably source glossy film from a wide range of manufacturers and vendors.

Matte film's popularity is surging, and its availability is improving rapidly. Most major suppliers now offer high-quality matte options. However, some smaller or regional distributors may have a more limited selection.

📝 Note for Printers: Always confirm stock levels with your specific supplier before committing to a large project requiring matte film. While it is becoming more common, ensuring your provider has it on hand prevents unexpected production delays.

Choosing between matte vs glossy dtf film depends entirely on the project's goals. This guide simplifies the decision by outlining the best scenarios for each finish. Printers can use these points to align their film choice with client expectations and production needs.

Select matte film when the final product requires a subtle, high-end feel. This finish excels in retail and fashion contexts where quality is paramount.

Premium Apparel: The design needs a soft-hand feel that integrates into the fabric, mimicking a traditional screen print.

Subtle Branding: The project involves sophisticated logos or artistic graphics that benefit from a non-glare surface.

High-Stretch Fabrics: The garment is made from activewear materials like spandex, requiring a print that moves without cracking.

Maximum Comfort: The design is large, and breathability is a key factor for the wearer's comfort.

Opt for glossy film when the design must be vibrant and command immediate attention. Its production speed also makes it a practical choice for high-volume jobs.

Promotional Items: The goal is to create eye-catching merchandise for events, trade shows, or marketing campaigns.

Children's Clothing: The design uses bright, bold colors that are enhanced by a shiny, fun finish.

High-Volume Orders: The project requires rapid production, making the hot peel process a significant advantage.

Maximum Vibrancy: The artwork needs its colors to appear as saturated and brilliant as possible.

Ultimately, the final decision in the matte vs glossy dtf film debate rests on balancing visual impact with the desired feel and production demands.

The matte vs glossy dtf film debate has no single winner. The choice is strategic and project-dependent. Printers select matte film for a premium, subtle look. They choose glossy film for maximum vibrancy and production speed. Testing both types helps a brand discover the best fit for its quality standards.

Glossy film is often easier for beginners. Its hot peel process simplifies the workflow and reduces the chance of errors associated with waiting for the transfer to cool completely.

Yes, printers can combine finishes on a single garment. This advanced technique requires multiple presses and careful alignment. It creates unique designs with varied textures for a custom look.

The garment color does not dictate the finish. Printers choose a finish based on the desired design aesthetic—vibrancy or subtlety—rather than the color of the fabric itself.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

In the industrial and agricultural packaging secto...

MoreWhen diving into Direct-to-Film (DTF) printing, on...

MoreBOPP Film, or Biaxially Oriented Polypropylene Fil...

MoreBOPP films, or biaxially oriented polypropylene fi...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

Tel: +86 17706217416

Add: Building L2A, No. 520, Lane 1588, Zhuguang Road, Hongqiao World Center, Qingpu District, Shanghai, China

User Comments

Service Experience Sharing from Real Customers

Michael Rodriguez

Graphic DesignerThe matte DTF film is perfect for my apparel designs. It gives a soft, premium feel that my clients love, unlike the glossy which can sometimes look cheap. The color accuracy and durability are outstanding.

Sarah Chen

Print Shop OwnerWe offer both matte and glossy options to our customers. The glossy DTF film provides vibrant, eye-catching colors for promotional items, while the matte is ideal for more sophisticated designs. Quality is consistent and reliable.

David Kim

Marketing ManagerUsed the glossy DTF film for a recent product launch campaign. The prints were incredibly sharp and the glossy finish made the colors pop on our trade show banners. Excellent contrast compared to matte finishes for this application.

Jessica Williams

Small Business OwnerAs a creator of custom mugs and phone cases, having both finishes is a game-changer. The matte film gives a modern, non-slip feel, while the glossy is perfect for photo reproductions. Both films transfer beautifully with no issues.